The difference between high-frequency welded fin tubes and serrated fin tubes

The difference between high-frequency welded fin tubes and serrated fin tubes

There are some differences in the manufacturing process and performance characteristics between high-frequency welded fin tubes and serrated fin tubes, as follows:

Manufacturing process

High-frequency welded fin tubes:

High-frequency welded fin tubes are fin tubes made by high-frequency welding.

It uses the heat generated by high-frequency current in the conductor to make the base tube and fins reach a molten state, and then after cooling and solidification, an integrated fin tube is formed.

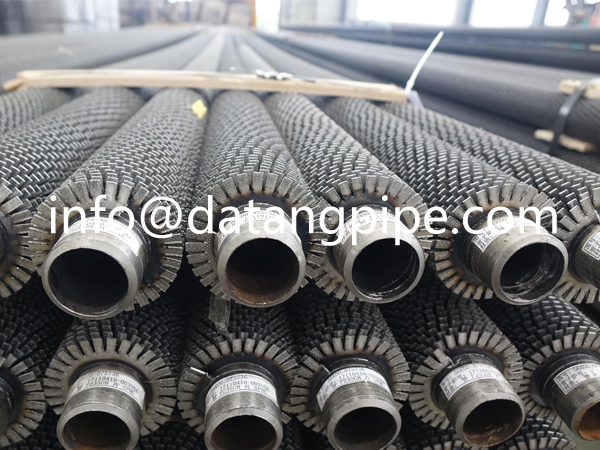

Serrated fin tubes are to open the steel strip before high-frequency welding of the fins.

Then the skin effect and high temperature of the high-frequency current are used to weld the steel strip after opening the teeth to the steel pipe.

Performance characteristics

High-frequency welded fin tubes:

Efficient heat transfer: It has a large heat transfer area, which can effectively improve the heat transfer efficiency and reduce the heat transfer thermal resistance.

Good corrosion resistance: Made of high-quality materials, it can adapt to various harsh working environments.

Strong wear resistance: The surface is smooth, not easy to accumulate scale, and can maintain heat transfer efficiency for a long time.

High reliability: The manufacturing process is mature, the quality is stable and reliable, and it can ensure long-term stable operation.

Wide application range: It is widely used in various fields such as chemical industry, electricity, and environmental protection.

Serrated fin tubes:

High welding strength: Since the contact area between the steel strip and the steel pipe after the teeth is increased, the welding strength is higher.

Good heat exchange efficiency: The fin teeth increase the turbulence effect and improve the heat exchange efficiency.

Anti-dust accumulation: The tooth design can better prevent dust accumulation and maintain heat exchange efficiency.

Summary

High-frequency welded fin tubes and serrated fin tubes are different in manufacturing process. The former directly connects the fins to the base tube through high-frequency welding, while the latter teeth the steel strip before welding. In terms of performance characteristics, both have the advantages of efficient heat transfer, corrosion resistance, and wear resistance, but serrated fin tubes may have more advantages in welding strength, heat exchange efficiency, and anti-dust accumulation.

Please note that the above information is for reference only. The specific choice of finned tubes needs to be comprehensively considered based on the actual application scenarios and needs.