Project Description

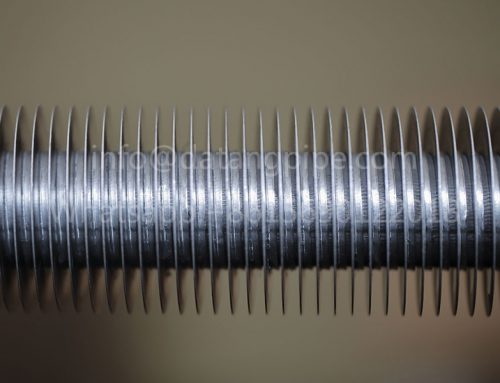

L-type fin tube(Концевая трубка L-типа)

- Leave Your Message

L-shape finned tube process:

Aluminum fins or copper fins are folded into an L shape and continuously spiral wound on the outer surface of the base tube under tension.

L-type finned tube working temperature:

150℃ Characteristics: winding process, high production efficiency, uniform pitch, good heat transfer, high finning ratio, the base tube can be protected from air erosion.

L-type fin tube application:

Mainly used in petrochemical, electric power, papermaking, tobacco, building heating and other industries air cooler, air heater and food industry, such as plant protein powder, starch and other spray drying system air heater.

The main function of finned tube is to increase the heating surface (or heat dissipation) and improve the heat transfer efficiency.

Technical requirements for finned tube production

Welding strength and stability

Tensile strength test: greater than 200MPa or partial tearing of the tube.

Weld seam width: greater than the thickness of fins, i.e., welding adhesion rate > 99% 1.3 Welding strength and stability: the first piece of each shift to do welding samples to meet the requirements of 2.1 or 2.2.

Bending test of welded seam: 20 degrees of bending of fins left and right, bending left and right twice, no cracks in welded seam.

Finned tube hammering test.

Strike the upper fin parallel to the tube until the fin falls off and the fin itself does not break.

If the test fails, the annealing function must be activated

Heat affected zone of finned tube

Measured by microscope with microhardness tester

Depth of heat affected zone on tube less than 0.5mm

Dimensional accuracy of L-finned tube products

3.1 Total length of fin segment -1mm ~ +1mm Accuracy of segment movement -0.5mm ~ +0.5mm

3.2 Pitch -0.2mm ~ +0.2mm

3.3 Perpendicularity of fins and tubes -1degree ~ +1degree

3.4 Flatness of the same group of butt-welded fins -0.2mm ~ +0.2mm except for the height difference caused by the thickness tolerance of the fins themselves.

3.5 Difference in height of butt-welded fins of the same group -0.2mm ~ +0.2mm, except for the height difference caused by the tolerance of the fin size itself.

3.6 Tolerance of center distance between two tubes -0.5mm ~ +0.5mm

3.7 Under the condition of the same tube material, the same pitch and number of fins, the length change of different finned tubes after welding is the same.

Welding speed of finned tube

Base tube O.D. 25~51, fin thickness 2mm, welding time less than 3 seconds per pair (excluding loading and unloading time and annealing time).