Project Description

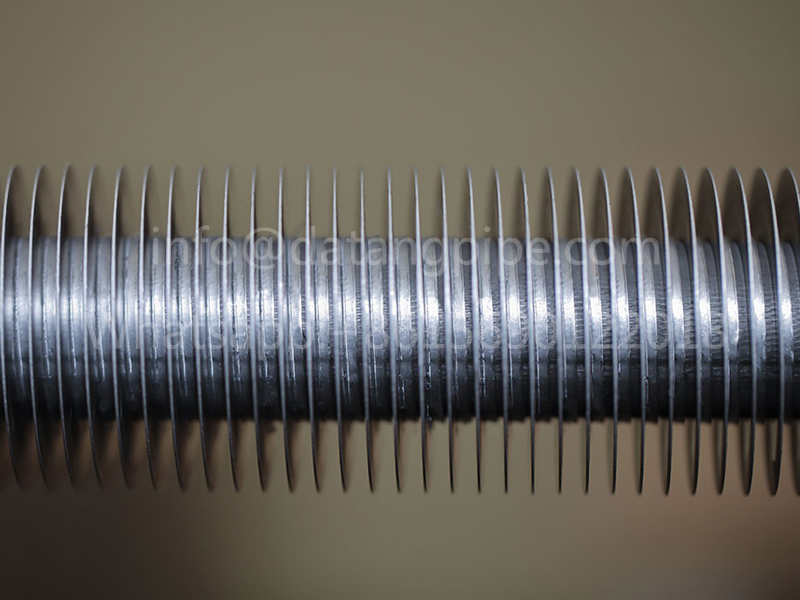

KL Type Copper Fins Finned Tube,KL Type Fin Tube

- Leave Your Message

KL Type Copper Fins Finned Tubes

KL type finned tube is a kind of manufacturing technology of the steel winding finned tube radiator.

KL type finned tube as one of the main heat dissipation elements, the winding finned tube has excellent heat dissipation performance, which is several times or even dozens of times that of the ordinary light tube radiator, the heat dissipation effect of the winding tube is good, and the winding finned tube is widely used in a variety of fields of large-scale use.

The service life of KL type finned tube radiator is generally up to 30 years, and its service life can be extended to 50 years if the user is correct in the process of using it.

The long service life of the finned tube radiator and the safe and reliable use of the wound finned tube are the main reasons why many users choose it.

KL type finned tube radiator can determine the processing technology according to different using environment, determine the type of radiator according to different using place, and determine the radiator with different specifications and models according to different temperatures required by users.

When choosing finned tube radiators, you must be clear about the conditions and specific requirements of your place of use so that you can choose a finned tube radiator that suits you and has a good heat dissipation effect.

The arrangement of the finned tube bundle can be in line or staggered. However, due to the closed eddy current area between the tubes of the finned tube bundle, it is easy to accumulate dust, and the structure size is large, so the staggered arrangement is generally adopted.

The transverse and longitudinal spacing of the staggered finned tube bundle has a great influence on the wear and tear of the heating surface, ash accumulation and flue gas velocity. Consideration is given to reducing wear, smoke velocity and space constraints.

The flue gas temperatures of both high and low temperature economizers increased after the modification of the finned tube economizer, indicating that the heat absorption of the finned tube economizer is higher than that of the light tube economizer. After the overhaul, the exhaust gas temperature was greatly reduced.

On the one hand, it is because the slag catcher was replaced during the overhaul, which strengthened the sealing of the flue wall and reduced the air leakage of the boiler. On the other hand, the coal economizer modification also reduced the exhaust gas temperature.

The heat transfer performance of KL type finned tube heat sink is discussed through some mechanical discussions and experiments.

KL type finned tube can be divided into many kinds according to different processes, such as toothed spiral finned tube, open seam spiral finned tube and integral continuous spiral finned tube.

The heat transfer coefficient of open seam spiral finned tube is higher than that of integral continuous spiral finned tube when other conditions are the same.

When we choose the wound finned tube, if the temperature is higher, we need to choose the slotted spiral finned tube as the heat transfer element of the radiator.

KL type wound finned tube: The outer surface of the base tube is knurled before the fins are continuously wound on the surface of the steel tube; after the fins are wound, the roots of the fins attached to the steel tube are also knurled to strengthen the bond between the steel tube and the fins.

This type of fin ensures better heat transfer characteristics than under L and LL fins. Operating temperature: 250°C