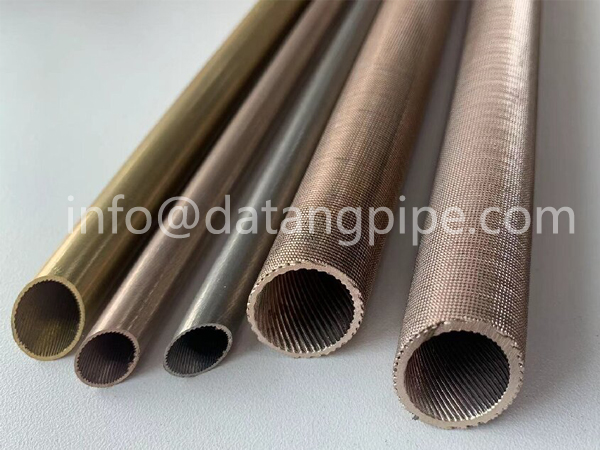

Cu90-Ni10 (B10 Alloy) Low Fin Tubes: Durable Heat Transfer Solutions for Corrosive Environments

Copper-Nickel alloys, particularly the 90/10 Cu-Ni variant (UNS C70600, commonly known as B10 or CuNi10Fe1Mn), are renowned for their exceptional resistance to corrosion, especially in seawater and marine atmospheres. B10 Low-Fin Tubes leverage this inherent corrosion resistance while significantly enhancing heat transfer efficiency through their specialized geometry. These tubes are a critical component in heat exchangers operating in demanding environments like offshore platforms, shipboard systems, desalination plants, and coastal power stations.

Cu90-Ni10 (B10 Alloy) Low-Fin Tubes

Material Advantages:

Superior Corrosion Resistance:

B10 alloy exhibits outstanding resistance to seawater corrosion, including erosion-corrosion, stress-corrosion cracking, and biofouling. This makes it vastly superior to copper or Admiralty brass in marine applications.

Good Biofouling Resistance:

The release of copper ions from the alloy surface helps inhibit the growth of marine organisms, reducing maintenance needs.

Excellent Fabricability:

B10 alloy can be readily formed, welded (using appropriate Cu-Ni filler metals), and brazed.

High Thermal Conductivity:

While lower than pure copper, the thermal conductivity of B10 alloy (typically ~50 W/m·K) is still significantly higher than many stainless steels and Titanium, enabling efficient heat transfer.

Good Mechanical Properties:

Offers a favorable combination of strength and ductility suitable for heat exchanger applications.

5/8 Inch 16mm Inner Grooved Red Copper Finned Tube Brass Aluminum Low Fin Tube

The Low-Fin Advantage:

Low-fin tubes feature integrally formed helical fins on the external surface. The “low-fin” designation typically refers to fins with a relatively low height-to-thickness aspect ratio. This geometry provides a substantial increase in the external heat transfer surface area (often 2.5 to 4 times that of a bare tube) while maintaining good mechanical strength and cleanability. The enhanced surface area dramatically improves the rate of heat transfer between the tube and the external fluid (often seawater, brackish water, or corrosive gases), making heat exchangers more compact and efficient.

Low Fin Tube Key Applications:

1. Marine Heat Exchangers:

Condensers, coolers, and evaporators in ships and offshore structures.

2. Desalination Plants:

Multi-stage flash (MSF) and multi-effect distillation (MED) heat recovery sections, condensers, and brine heaters.

3. Power Generation:

Condenser tubes for coastal and offshore power stations utilizing seawater cooling.

4. Chemical and Process Industries:

Coolers and condensers handling corrosive process streams or cooling water.

5. Oil & Gas:

Offshore platform cooling systems.

C-706 316 Inner Grooved Copper Nickel Finned Tube Low Fin Tube

Cu90-Ni10 (B10) Low-Fin Tube Key Parameters

- Parameter Value / Specification Notes

——————————————————————————————————————

Common Alloy Designation UNS C70600, CW353H, CuNi10Fe1Mn B10 is the common commercial name

——————————————————————————————————————

Nominal Composition Cu: 88.6 min % Typical composition per

Ni: 9.0 – 11.0 % ASTM B111 / B466

Fe: 1.0 – 2.0 %

Mn: 0.5 – 1.0 %

Zn: 1.0 max %

Pb: 0.05 max %

Impurities: Balance

——————————————————————————————————————

Density ~8.94 g/cm³

——————————————————————————————————————

Thermal Conductivity ~45 – 50 W/m·K At 20°C

——————————————————————————————————————

Coefficient of Thermal Expansion ~16.5 x 10⁻⁶ /K 20-300°C

——————————————————————————————————————

Specific Heat Capacity ~377 J/kg·K At 20°C

——————————————————————————————————————

Electrical Resistivity ~19 μΩ·cm At 20°C

——————————————————————————————————————

Tensile Strength (Annealed) Min. 275 MPa (40 ksi) Typical: 310-380 MPa

——————————————————————————————————————

Yield Strength (0.2% Offset, Min. 100 MPa (15 ksi) Typical: 110-170 MPa

Annealed)

——————————————————————————————————————

Elongation (Annealed) Min. 30% (in 50mm)

——————————————————————————————————————

Maximum Recommended Operating ~260°C (500°F) For heat exchanger service

Temperature (Continuous)

——————————————————————————————————————

Fin Geometry (Typical Low-Fin) Fin Height: 0.8 – 1.5 mm Specifics vary by manufacturer

Fin Pitch: 19 – 40 fins per inch & application

(0.6 – 1.6 mm)

Fin Root Thickness: ~80-90% of wall thickness

Surface Area Ratio: 2.5 – 3.5 (vs. bare OD)

——————————————————————————————————————

Tube Dimensions (Example Range) Outside Diameter (Bare OD): Standard sizes available;

12.7 – 25.4 mm (0.5″ – 1″) custom possible

Wall Thickness:

0.9 – 2.1 mm (BWG 18 – 12)

Lengths: Up to 12+ meters

——————————————————————————————————————

Standards (Typical) ASTM B111, B466, B543, B608 Covers seamless condenser &

heat exchanger tubes

Low Finned Tube Conclusion: Cu90-Ni10 (B10) Low-Fin Tubes offer an optimal blend of high thermal efficiency, outstanding corrosion resistance in seawater and marine environments, and good mechanical properties. The integrally formed low fins provide a significant increase in heat transfer surface area, enabling the design of more compact, efficient, and durable heat exchangers. Their proven performance makes them the material of choice for critical heat transfer applications where reliability and longevity in corrosive conditions are paramount. When specifying, ensure parameters like composition, dimensions, fin geometry, and applicable standards meet the specific requirements of the heat exchanger design and operating environment.