Project Description

- Product Name: ODM / OEM 18 Years Factory Finned Tube Types-L LL KL Fin Tubes

- Leave Your Message

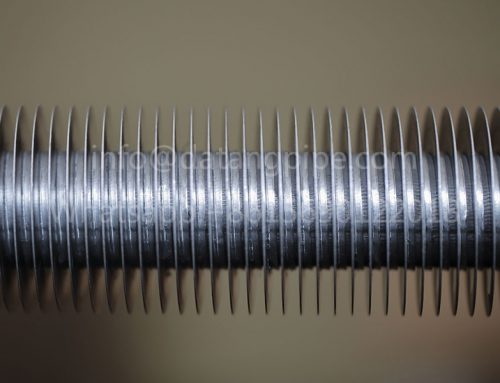

Wound fin tubes are divided into L-type, LL-type and KL-type fin tubes, according to their processing technology, characteristics, and use environment.

Here is the professional English translation of the specifications for L-type, LL-type, and KL-type finned tubes:

I. Core Classification & Process Characteristics

-

L-Type Finned Tubes

- Process: Aluminum or copper fins folded into an L-shape and spirally wound onto the base tube under tension.

- Performance: Fin-to-tube bonding relies on mechanical tension. Maximum operating temperature: 150°C.

- Applications: Heating radiators, low-temperature heat exchange systems (e.g., food drying equipment).

-

LL-Type Finned Tubes

- Process Upgrade: Based on L-type, fins fully cover the base tube surface at the root, minimizing gaps.

- Enhanced Performance: Improved corrosion resistance; max. operating temperature: 170°C.

- Use Cases: Petrochemical/power industry air coolers and corrosion-prone environments.

-

KL-Type Finned Tubes

- Core Process: Base tube pre-knurled → fins wound → root re-rolled, increasing contact area by 50%.

- Advantages:

- Lower contact thermal resistance → superior heat transfer vs. L/LL types;

- Withstands thermal cycling → no loosening; max. operating temp.: 250°C.

- Typical Applications: High-temperature/pressure scenarios (e.g., power plant waste heat recovery, industrial boilers).

II. Key Performance Comparison

| Type | Max. Temp. | Heat Transfer | Corrosion Res. | Process Complexity |

|---|---|---|---|---|

| L | 150°C | Baseline | Moderate | Low |

| LL | 170°C | Moderate | High | Medium |

| KL | 250°C | High | Superior | High |

| Data synthesized from24 |

III. Selection Guidelines

- Corrosion Priority: Humid/corrosive environments (e.g., marine, chemical) → LL-type;

- High-Temp. Scenarios: Steam exchange/waste heat recovery (>200°C) → KL-type;

- Cost Efficiency: Low-temperature civil heating → economical L-type.

Note: All types use carbon steel/stainless steel/copper base tubes with aluminum/copper fins. Material selection must align with medium compatibility (e.g., pH).