Why Are Embedded G-type Fin Tubes Grooved?

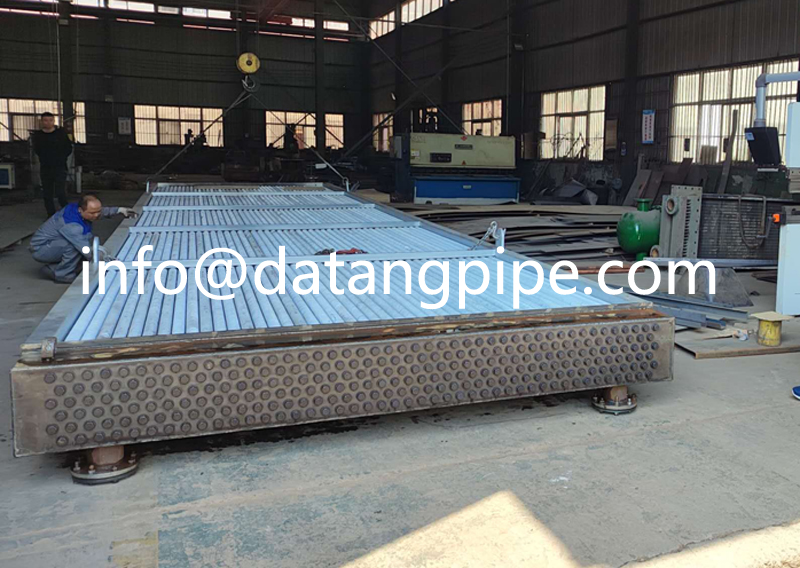

Embedded G-type fin tubes are pre-grooved in the steel tube, and the fins are then spirally wound into the grooves. This grooving process optimizes the connection between the fins and the base tube, increasing the fin surface area.

The advantages of grooved embedded G-type fin tubes are primarily reflected in the following aspects:

Grooving embedded fin tubes optimizes heat dissipation performance

The groove design increases the fin surface area. The addition of the groove structure further expands the heat dissipation area. Especially in high-temperature environments, the groove structure enhances heat radiation and aids convective heat transfer.

Grooving embedded fin tubes improves thermal conductivity

The groove structure disrupts the fluid boundary layer, reducing thermal resistance, accelerating heat transfer from the base tube to the fins, and increasing heat transfer speed.

Grooving embedded fin tubes improves structural strength

The grooving process optimizes the connection method (such as expansion joints or welding) between the fins and the base tube, strengthening the bond and reducing the risk of detachment due to vibration or pressure fluctuations. G-type fin tube slotting adapts to complex operating conditions.

The slotting pattern allows for flexible adjustment of fin spacing and arrangement to meet the flow requirements of different media (such as gas-liquid and liquid-liquid heat exchange), enhancing the equipment’s adaptability to complex operating conditions.

The specific advantages require a comprehensive evaluation based on the slot shape (e.g., straight, corrugated), material (copper/aluminum/steel), and process parameters.

Email:info@datangpipe.com

Whatsapp:+86 15690122018