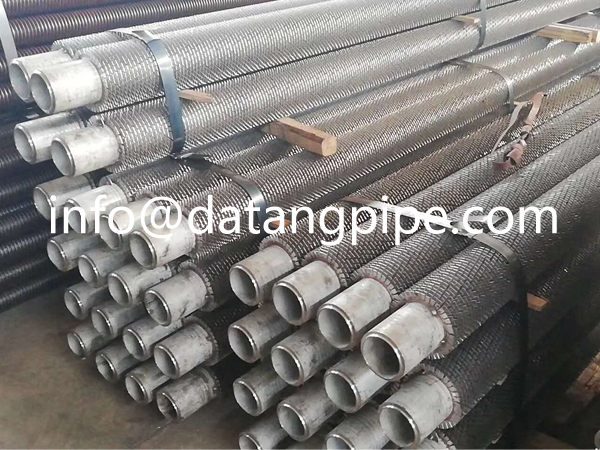

Basic Guide to Serrated Fin Tubes

Heat exchangers are complex devices that require a careful selection of tubes to achieve optimal heat transfer efficiency. Serrated finned tubes are becoming increasingly popular in various industries due to their unique design and ability to improve heat exchange processes.

What Are Serrated Finned Tubes?

Serrated finned tubes stand out as a specialised category of heat exchanger tubes crafted to enhance the efficiency of heat transfer processes. What sets them apart is the incorporation of serrations – small notches or grooves along the fins. These serrations are strategically designed to disrupt the air or gas flow boundary layer over the finned surface, leading to improved heat transfer characteristics.

The primary objective of these serrations is to create turbulence in the airflow, preventing the formation of a stagnant boundary layer that could impede the heat exchange process. This unique design significantly differentiates serrated finned tubes from their traditional counterparts, making them particularly suitable for applications where heightened heat transfer efficiency is crucial.

The following table shows Datang’s manufacturing capabilities for helical serrated finned tube:

| Weld Process | GMAW |

| Tube/Pipe Size | 1.00″ to 12.75″ outside diameter |

| Fin Height | 0.375″ to 1.25″ |

| Fin Segment Width | 5/32″ or 5/16″ |

| Fin Thickness | 20ga (.035″) to 16ga (.060″) |

| Fin Pitch | 1 to 7 fins per inch |

| Materials | Any material combination that can be arc welded |

| Tube Length | No practical limit |

Technical Details

Base Tube Details

Tube Diameter : 20 mm OD Min to 219 mm OD Max.

Tube Thickness : Minimum 2 mm up to 16mm

Tube Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, duplex Steel, Super Duplex Steel, Inconel, High Chrome High Nickle & Incolloy, CK 20 material and some other material.

Fin Details

Fins Thickness : Min. 0.8 mm to Max. 4 mm

Fins Height : Min 0.25” (6.35 mm) To Max.1.5” (38 mm)

Fin Density : Min 43 Fins per Meter to Max. 287 Fins per Meter

Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, Duplex Steel and Incolloy.

How Are Serrated Finned Tubes Manufactured?

The manufacturing process of serrated finned tubes involves specialised steps, ensuring precision and quality for optimal performance. A brief overview of the critical manufacturing stages provides insight into the complexity of producing these innovative tubes:

1. Tube Production:

The journey begins with the production of the base tube, often composed of materials like alloy steel. For precision and uniformity, seamless tubes, especially those cold-drawn, are frequently preferred. This initial step sets the foundation for a tube that can withstand the rigours of diverse industrial applications.

2. Fin Formation:

The fins are then meticulously attached to the tube surface using advanced techniques. The process involves machining or extruding the serrations onto the fins, a critical step that demands precision to ensure the effectiveness of the serrations in disrupting the boundary layer. The intricacy of this process emphasises the importance of precision engineering in achieving optimal heat transfer efficiency.

Serrated Finned Tube Quality Control:

Stringent quality control measures are implemented throughout the manufacturing process to guarantee the structural integrity and performance of the finned tubes. Non-destructive testing methods, such as ultrasonic testing and visual inspections, are commonly employed to identify and rectify any defects that may compromise the functionality of the tubes.

Applications of Serrated Fin Tubes

Serrated fin tubes, with their efficient and stable heat exchange performance, are widely used in the chemical, petroleum, and pharmaceutical industries. They are primarily used for heat exchange with high-temperature, high-pressure, and highly corrosive media such as steam, hot water, cold water, refrigerants, solvents, and brine. Compared to conventional heat exchangers, serrated fin tubes offer advantages such as high heat transfer efficiency, low resistance, excellent impact resistance, light weight, and compact structure, making them highly popular among users.

Advantages of Serrated Fin Tubes

1. Improved Thermal Performance:

The primary benefit of serrated fin tubes is their significantly improved thermal performance. Boundary layer disruption and optimized surface area enhance heat transfer efficiency.

2. Energy Efficiency:

Enhanced heat transfer efficiency directly translates into higher energy efficiency.

3. Extended Equipment Life:

The anti-fouling and durable construction of serrated fin tubes help extend the life of heat exchange equipment. Preventing fouling reduces the frequency of maintenance interventions and minimizes downtime.

4. Customization Options:

The flexible design of serrated fin tubes allows companies to tailor heat exchanger systems to their needs. The ability to customize materials, sizes, and configurations ensures that the fin tubes can meet the unique requirements of different industries and applications.

5. Cost-Effective Solution:

Serrated fin tubes combine improved thermal performance with greater energy efficiency and longer equipment life.