Project Description

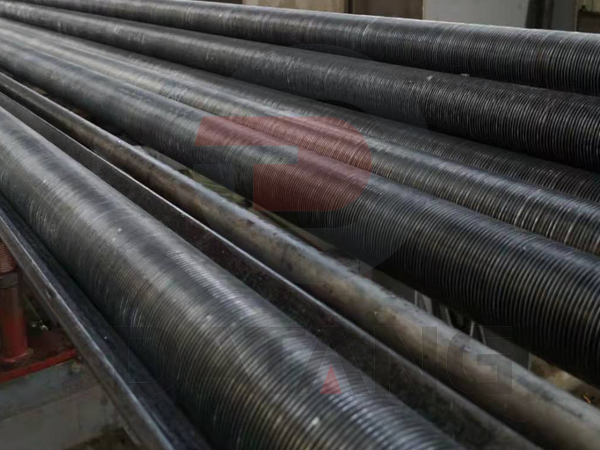

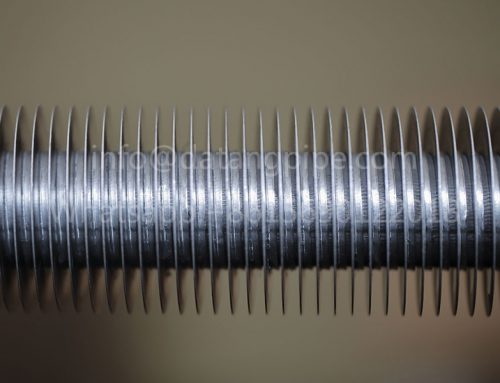

L Type Finned Tube is a finned tube made of aluminum fin tape or copper fin tape folded into an L-shaped spiral under tension and wrapped tightly around the outer surface of the base tube.

The tension in the fin strips of the L Type Finned Tube wraps around the tube, causing the fin feet to press forcefully against the tube, holding the fins firmly in place. L Type Finned Tube is usually used in air coolers in petrochemical, power, paper, tobacco, building heating and other industries as well as heat exchangers in power plants (electricity, nuclear, thermal and geothermal power plants), the maximum operating temperature can reach 230°C.

L Type Finned Tube for Heat Exchanger Quick Details:

Fin type: Solid plain

Fin Tube Type:L Type

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

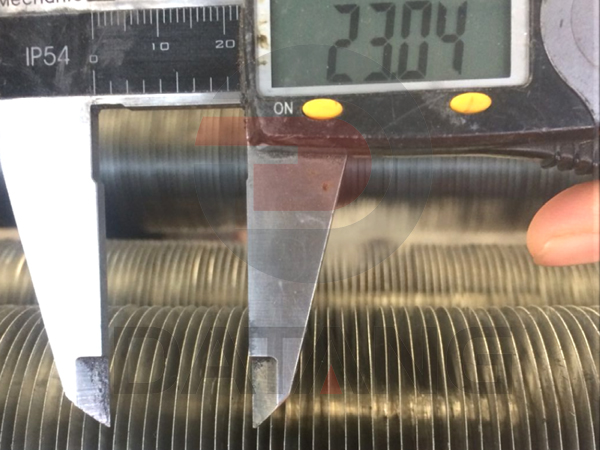

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

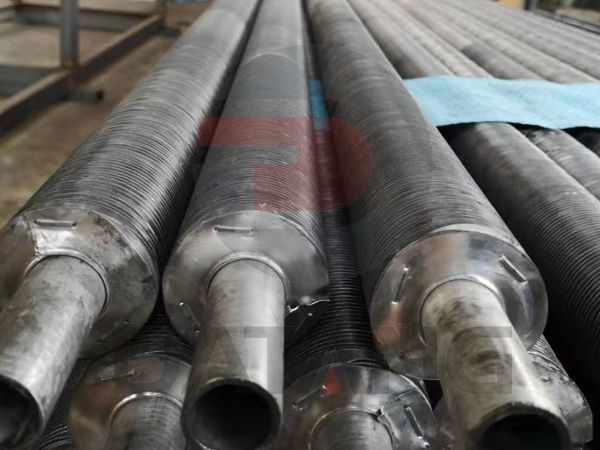

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Common Specifications of L Type Finned Tube for Heat Exchanger

| All dimensions are in Inches and specification upon your requests | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

We can customize L Type Finned Tube for heat exchanger according to your drawings

Example:

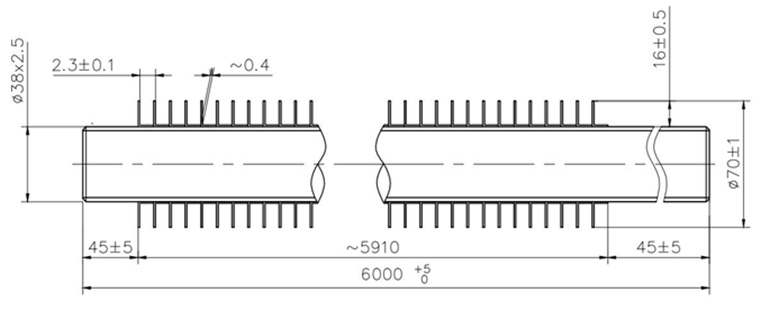

L Type Finned Tube for Heat Exchanger drawing

Manufacturing Process:

Fin strips (usually aluminum and copper) are folded into an L shape and wound under tension on the surface of the base tube. The feet of the fins are connected together and cover the surface of the fins.

L Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Core Tube Material | |

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the L-shaped tension wound finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of L Type Finned Tube

1. The trapezoidal section formed by the calendering of L Type Finned Tube for heat exchanger is consistent with the distribution of heat flow density, the tubes are tightly combined, and the thermal efficiency is high, which eliminates the contact heat caused by the gap between the tubes and the finned tube. resistance, the fin spacing is uniform, and the heat transfer performance is good.

2. The tube can withstand temperatures up to 150°C and there is no risk of atmospheric corrosion or thermal stress.

3. The L-type finned tube provides the contact area between the fin strip and the surface of the tube to protect the tube wall from atmospheric corrosion.

4. This L TYPE design is much more economical than LL, KL or even G-embedded types.

5. Maximum operating temperature: 230°C

Application of L Type Finned Tube

1. Highly corrosive systems (condenser, evaporator, desalination, fertilization, urea system, ammonia, gas, corrosive acid);

2. Air coolers in petrochemical, electric power, paper, tobacco, building heating and other industries;

3. Air heaters and air heaters for spray drying systems such as vegetable protein powder and starch in the food industry;

4. Heat exchanger installations in power plants (electrical, nuclear, thermal and geothermal power plants).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

Wound sheet type The L type fin tube wound tube is easy to manufacture and cheap, and it is widely used in air coolers for petrochemical industry. However, because the aluminum sheet is fastened to the surface of the steel pipe by the initial stress of winding, when the temperature of the pipe wall is high, the tension of the fin is greatly reduced, the fin starts to loosen, and the contact thermal resistance increases, so its use temperature is relatively low, generally low At 130°C.

Therefore, the L type finned tube wound tube is suitable for occasions with relatively stable working conditions and no sudden changes in temperature; it is also not suitable for occasions with large vibrations. The base tube is partially covered by the bent legs between the fins, and its resistance to atmospheric corrosion is general, which is between the DR type and the G type.

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.