Advantages of laser welded finned tube

Laser welded finned tube is a product of better technology, which has irreplaceable advantages.

1、The thickness of the base tube of laser welded finned tube can be 0.8-1.5mm, and the thickness of the plate fin type can be 0.3-1mm, which greatly saves the material cost compared with other production processes.

2、Laser welded finned tube has a large melting rate, which can avoid interstitial corrosion, improve the service life and reduce the heat transfer heat transfer index.

3、Improve the limitation of raw materials, can use different raw materials for processing.

4, laser welded finned tube is easy to secondary processing, can immediately carry out the wind disk and bends.

5, electric welding welding heat-affected zone is small, metallurgical analysis of the transformation is small, to promote the processing of small tube by laser welding finned tube becomes very likely.

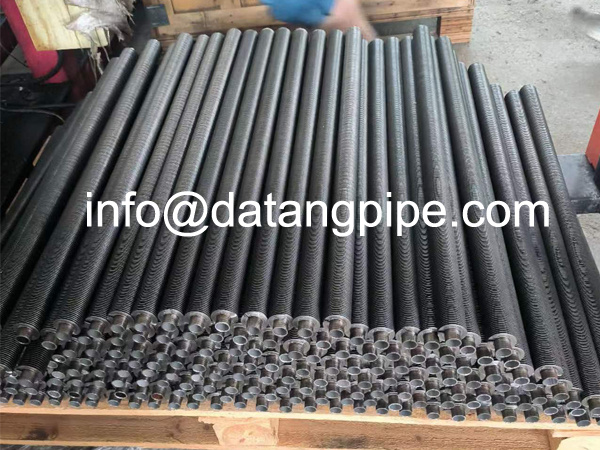

Laser welded finned tube is a heat exchanger and condenser material, with strong heat transfer performance, but also has a strong corrosion resistance, resistance to cleaning, resistance to abrasion and erosion performance, and excellent compressive strength and bending strain and plasticity properties, easy to process and manufacture.