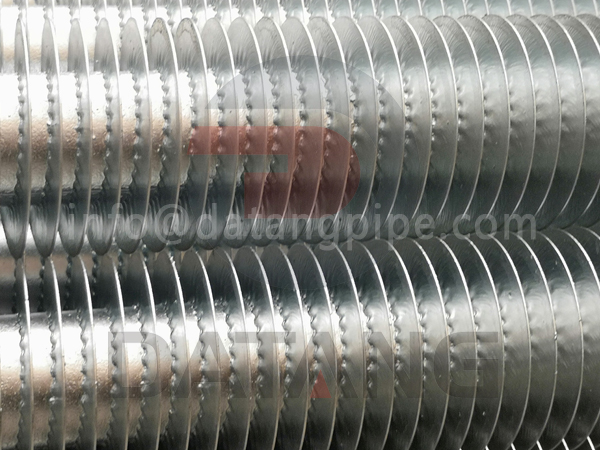

Various sectors rely on the high-quality high finned tubes from DATANG fin tube. They form a crucial part in the production of air-cooled heat exchangers, where basically these high finned tubes provide the transfer of heat.

High finned tubes with applied fins are manufactured by wrapping a fin around the base of the tube – providing the required characteristics for the process application.

Helical high finned tubes

TYPES OF HELICAL HIGH FINNED TUBES:

EXTRUDED FINS

Tubes with extruded fins provide complete protection to the base of the tube as they are hardened during the extrusion process – making them stronger than applied fins.

Upper temperature limit: 350°C

Tube Material: Any standard material we stock or is requested

Fin Material : Aluminium

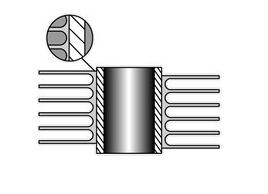

L FIN (OR WRAPPED FIN)

The extruded fin tube is wrapped around the tube and secured at each end to provide some surface protection. L Fin tubes are renowned for maximum heat transfer and enhanced corrosion protection – suiting moderate temperature cooling applications.

Upper temperature limit: 120°C

Tube Material: Any standard material we stock or is requested

Fin Material : Aluminium or Copper

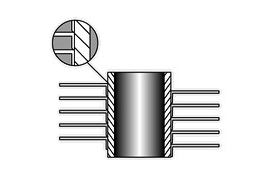

LL FIN (OR OVERLAPPED FIN)

The fin is wrapped around the tube with an overlapping foot and secured at each end. It offers excellent corrosion resistance and is often used as an alternative for expensive extruded fins in corrosive environments.

Upper Temperature limit: 180°C

Tube Material: Any standard material we stock or is requested

Fin Material : Aluminium or Copper

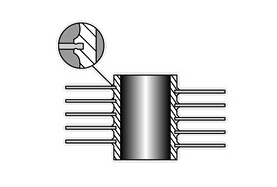

G FIN TUBE (OR EMBEDDED FIN)

Fin is embedded into the outer wall of the tube, but gives no surface protection. The finned tube is used in general use for continuous process applications; ie refineries, petrochemical, fertilizer and gas plants.

Upper temperature limit: 450°C

Tube Material : Harder material (Please contact us for guidance)

Fin Material : Aluminium , Copper or steel

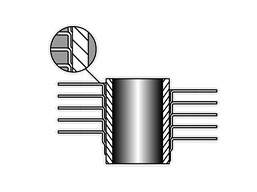

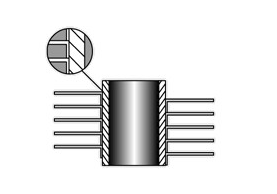

KL FIN (OR KNURLED L FIN)

The KL finned tube is manufactured like the ‘L fin’ only the fin is wrapped around the tube and the foot is rolled into the outer surface of the pre knurled tube. KL finned tubes give good surface protection to the tube and improve heat transfer.

Upper Temperature limit: 250°C

Tube Material: Any standard material we stock or is requested

Fin Material : Aluminium or Copper

With more than 20 years of experience in the production of (high) finned tubes, DATANG fin tube knows what it is talking about when it comes to the application of this quality product. In addition to high finned tubes, we also offer you low finned tubes. Our technical advisors are happy to tell you more about the differences between the two products. On this page you can read more about the application and production of our high finned tubes. Are you already using it in your production process?

APPLICATION OF OUR HIGH FINNED TUBES

As already mentioned, DATANG fin tube’s high finned tubes are used, among other things, in the production of air-cooled heat exchangers. High finned tubes basically consist of a metal tube, surrounded by an aluminum strip or sometimes copper strip. This strip can be applied in different ways. A distinction is made, among others, between a type L, a type KL, a type LL, a type G (embedded) or a type extruded finned tubes. With extruded finning the fins are produced our of an aluminium tube instead of aluminium strip. The metal tube can be made of different types of metal, depending on the intended application of the high finned tubes.

Within a heat exchanger, the hot medium runs through the finned tubes and heats the tube and the aluminium fins. The metal tube heats up, after which it transfers its heat to the aluminum fins. These fins then ensure that the heat is transferred into the ambient air.