Extruded Fin Tubes are Classified for Fin Fan Cooler Heat Exchanger

Extruded fin tubes for fin fan cooler heat exchanger

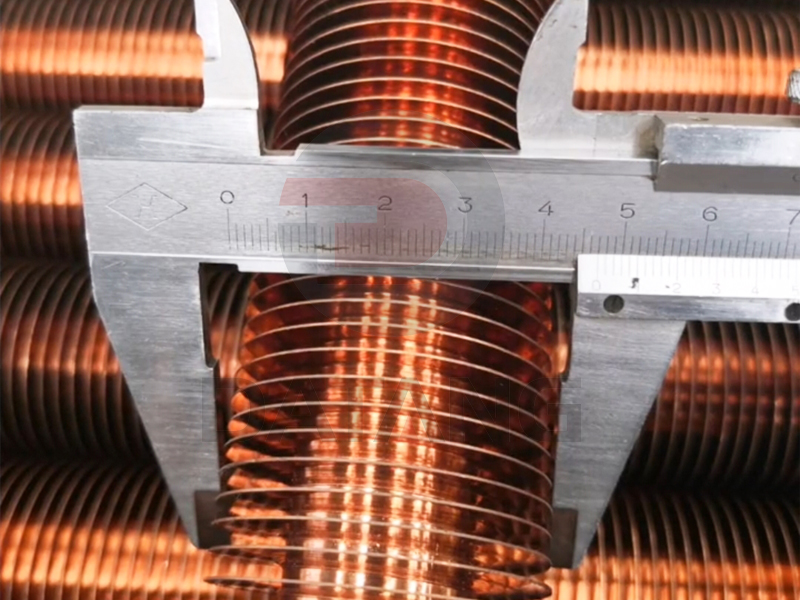

Extruded finned tube is a finned tube with a special structure.

It combines the fins and the base tube tightly together through the extrusion process.

This finned tube has some significant characteristics and advantages. First, the extrusion process makes the bonding strength between the fins and the base tube high, which can withstand large pressure and temperature changes and is not prone to fin shedding. Secondly, the fins are evenly distributed, which helps to improve the heat exchange efficiency.

Extruded finned tubes are commonly used in various heat exchange equipment, such as economizers and heat exchangers of industrial boilers.

In practical applications, such as in some high-temperature and high-pressure industrial heat exchange scenarios, extruded finned tubes can operate stably, effectively realize heat exchange, and improve energy utilization efficiency.

1.Steel-aluminum composite fin tube

The processing technology of cold-rolled aluminum-steel fin tube is to first process aluminum tube and steel tube into bimetallic composite tube, and then mechanically cold-roll it into fins. This fin tube uses the physical properties of aluminum tube, takes steel tube as core material, and cold-rolled aluminum fins as one-piece fin tube. Widely used in steel, petroleum, chemical, machinery, shipbuilding, power station, hospital and food industries.

1. High heat transfer performance and low contact thermal resistance;

2. The contact area between fin and tube is large, and the connection is tight and reliable;

3. Good corrosion resistance and stable long-term performance;

4. The fin has good rigidity and is not easy to deform.

2.Copper-aluminum composite fin tube

Copper-aluminum composite fin tube is made of copper-aluminum composite tube after compounding. It has the characteristics of tight bonding, small thermal resistance, good heat transfer performance, high strength, small flow loss, strong corrosion resistance, small deformation, and long service life under long-term cold and hot conditions. In the wet cooling of heating and air conditioning, the condensed water on the surface of the fin is easy to remove, and it is not easy to scale and accumulate dust in heat exchange occasions such as coaxial heating.

3.Pure aluminum composite fin tube

The single metal composite fin tube is rolled as a whole by an aluminum tube. The pure aluminum rolled fin tube has no contact thermal resistance, high strength, heat resistance, mechanical vibration resistance, good thermal expansion performance, and a large expansion heat exchange area.

4.Pure copper composite fin tube

The copper fin tube is a heat exchange element. In order to improve the heat exchange efficiency, fins are usually added to the surface of the heat exchange tube to increase the outer surface area (or inner surface area) of the heat exchange tube, thereby achieving the purpose of improving the heat exchange efficiency.

The integral rolled fin tube has no contact thermal resistance, good heat transfer performance, high strength,

heat resistance, mechanical vibration resistance, and good thermal expansion performance.

Cangzhou Datang Steel Pipe Co., Ltd

Location: Yanshan County, Cangzhou City, Hebei Province, China

Core Products:

- Extruded fin tubes

- Embedded G-type fin tubes

- High frequency welded spiral fin tubes

- Low fin tubes

- Laser welded fin tubes

- L/LL/KL fin tubes

- Internal fin tubes

- Elliptical fin tubes

- Longitudinal fin tubes

- Serrated fin tubes

Key Features:

- Specialized in energy-saving and environmental protection equipment

- ISO 9001 certified quality management system

- Rigorous quality control (100% water pressure tests & fin welding strength pull tests)

- Superior material properties: pressure-resistant, corrosion-resistant, oxidation-resistant

Company Strengths:

- 20 years of manufacturing experience

- Daily production capacity: 10,000+ fin tubes

- Advanced equipment: laser welders, high-frequency welders, rolling welders, tensile testers

- Comprehensive testing facilities: water pressure testing environment, corrosion testing lab

- Strong R&D department for technical support

- Efficient sales team with competitive pricing

- Global customer base

- 1-year product warranty

Additional Capabilities:

- Operation and maintenance project support

- Heat exchanger solutions

We welcome new partnerships and look forward to future cooperation opportunities.