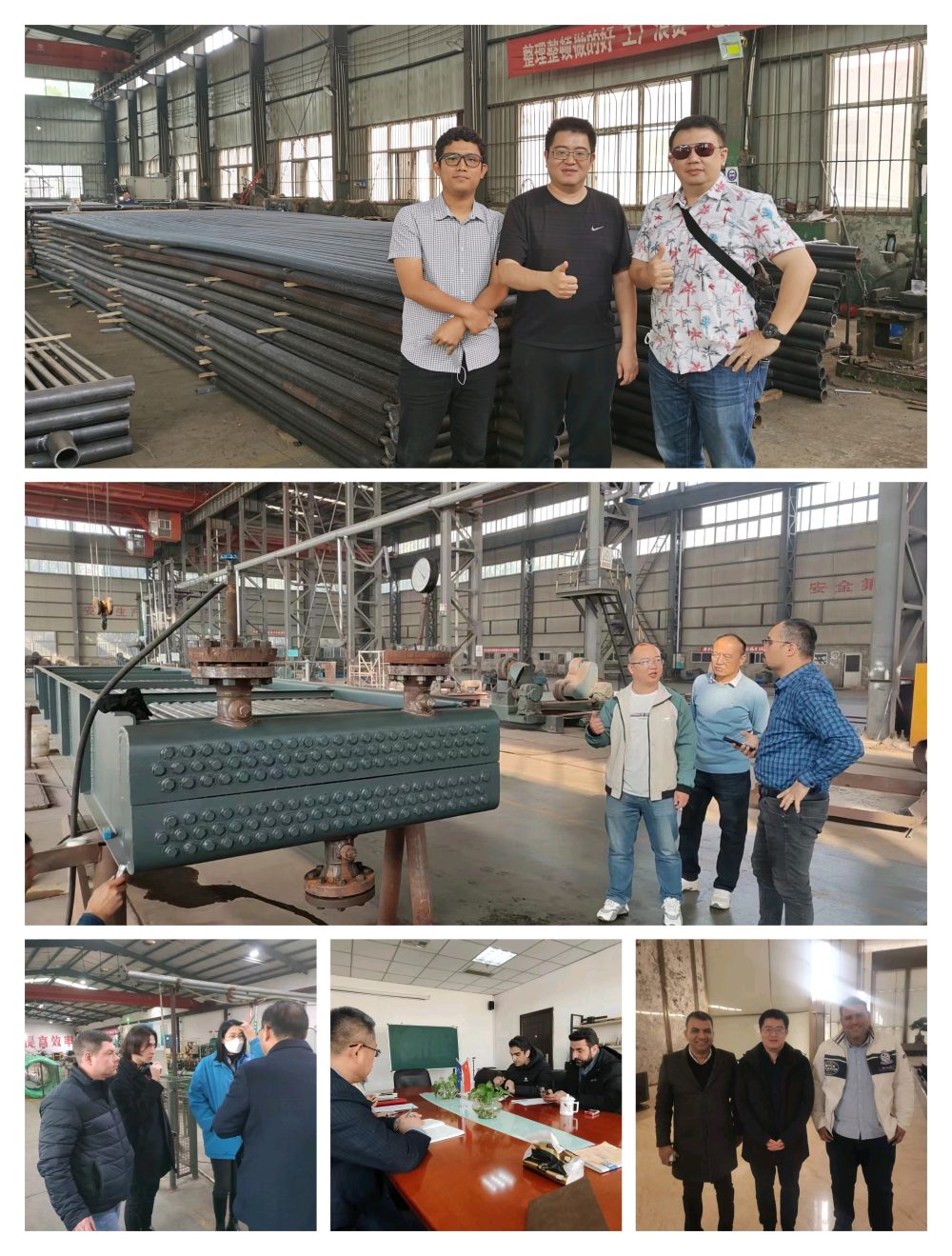

G type Embedded Fin Tube for heat exchanger Manufacturer in China

G type Embedded Fin Tube for heat exchanger Manufacturer in China

Embedded Fin Tube is a kind of heat exchanger element made by processing steel tube and fins separately and then inlaying fins on the surface of steel tube. This type of finned tube is characterized by high heat transfer efficiency and corrosion resistance, but the manufacturing process is more complicated and the cost is higher.

Embedded Fin Tube is pre-processed in the steel tube with a certain width and depth of the spiral groove, and then on the lathe to set the steel strip on the steel tube. In the winding process, due to a certain pre-tensioning force, the steel strip will be tightly strung in the spiral groove, thus ensuring a certain contact area between the steel strip and the steel tube.

In order to prevent the steel belt from springing off, the ends of the steel belt are welded to the steel pipe. This inlay process requires a certain side gap between the steel strip and the spiral groove to facilitate the inlay, but if the side gap is too small to form an interference, the inlay process is difficult to carry out smoothly.

In addition, the winding of the steel strip will always have a certain amount of rebound, the result of which makes the steel strip and the bottom surface of the spiral groove can not be well connected.

Embedded Fin Tube process: the fins are tightly embedded in the outer surface of the mechanically slotted base tube.

Base tube material: carbon steel, alloy steel, stainless steel, duplex steel, copper tube.

Fin: Aluminum 1060, Aluminum 1100, T2 copper.

Usage occasions: air cooler, heat exchanger, air warmer, coal economizer

Application areas of Embedded Fin Tube:

- Petroleum, chemical and petrochemical industries.

- Petroleum, chemical and petrochemical industries

- Natural gas processing

Steel industry: blast furnace and converter systems

- Power generation: steam turbine exhaust gas condensation, condensate contact cycle cooling condensation, fossil and nuclear power plants

- Air conditioning (Freon, ammonia, propane)

- Waste incineration equipment

- Compressor coolers, etc.

What are the precautions for disassembling and installing G-type finned tubes?

1.Before disassembling the G-type Embedded Fin Tube, the standard length of plate bundle compression needs to be measured and recorded accordingly. The next installation needs to pick the parts according to the corresponding standards; check the gasket for sealing. If sticking between the grooves, you can use a small screwdriver to separate them, stabbing from a relatively simple stripping position, and then complete the separation.G-type Embedded Fin Tube gaskets must not be damaged, otherwise it will affect the daily sealing effect.

2.check whether the G-type Embedded Fin Tube is poorly perforated, you can choose a magnifying glass or lighting inspection methods; assuming that the inspection process found between the entrance and exit of the short tube and the channel of the foreign body, the surface filter simply lose power, you need to clean immediately. Common cleaning methods are chemical cleaning and technical direct cleaning.

3.Assuming that there is scarring in the plate of heat exchange in the G-type Embedded Fin Tube, remember not to deal with it with a wire brush so as not to reduce the corrosion function of the plate. If the stains and rust are obvious, you can use the powder to remove the stain to wash. The water after washing must not contain corrosive components such as sulfur, acid, salt, etc.; Check whether the plate of G-type finned tube is deformed. If the degree of deformation exceeds the allowable range, it needs to be replaced.

4.The sealing gasket has an extraordinary effect on the plate of G-type Embedded Fin Tube. There shall be no fixed particulate matter in the groove, such as iron slag, sand, etc.; the titanium plate shall not be exposed to open flame during disassembly to avoid poor oxidation. Finned tube surface appearance should also be neat, try not to scratch.