Industrial steel aluminum finned tube heat exchanger

- Overview and characteristics of industrial steel aluminum finned tube heat exchangers

Industrial steel aluminum fin tube heat exchanger is a type of heat dissipation equipment widely used in the industrial field. It combines the durability of steel tubes with the efficient heat dissipation of aluminum fins, providing an efficient solution for heat management in industrial production processes. . Its characteristic lies in the close combination of fins and steel pipes, which allows heat to be quickly and evenly transferred from the steel pipes to the fins, and then dissipated into the air through the fins, achieving efficient heat exchange.

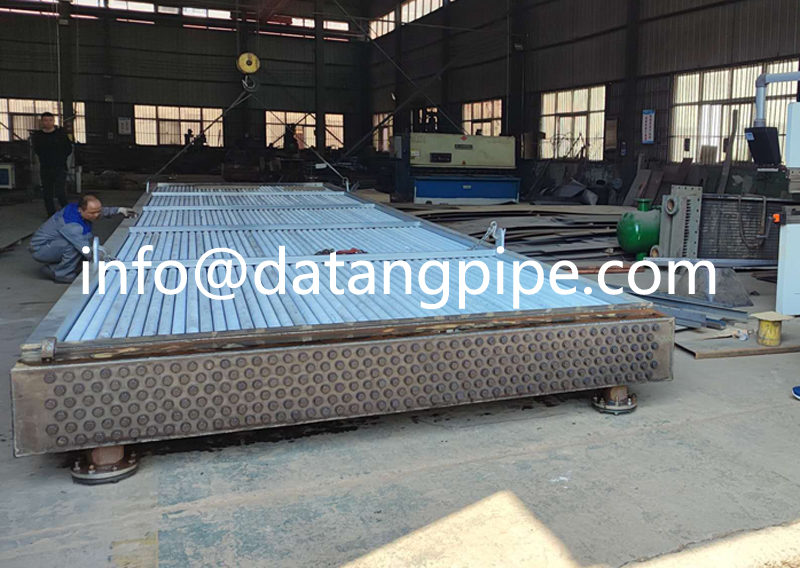

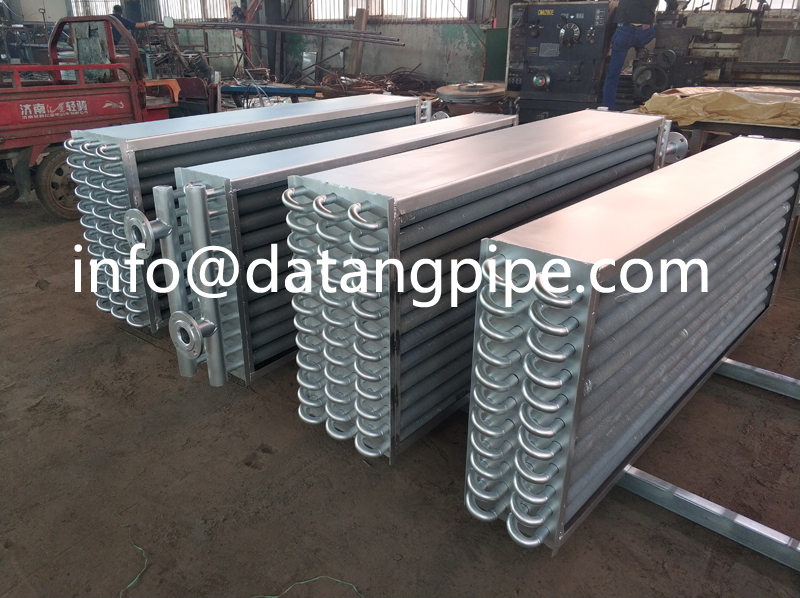

- Structure and manufacturing process of industrial steel aluminum finned tube heat exchanger

The structure of the industrial extruded fin tube heat exchanger is mainly composed of steel tubes, aluminum fins and connectors. As the main heat conduction part, steel pipes are usually seamless steel pipes or welded steel pipes, which have excellent strength and corrosion resistance. The aluminum fins are closely combined with the steel pipe through processes such as mechanical expansion or high-frequency welding to form a large heat dissipation surface. In terms of manufacturing process, steel-aluminum finned tube heat exchangers use advanced production lines for automated production to ensure the stability and consistency of product quality.

- Performance advantages of industrial steel aluminum finned tube heat exchangers

Industrial steel aluminum finned tube heat exchangers have significant advantages in performance. First of all, it has high heat dissipation efficiency and can quickly dissipate heat into the air to meet the urgent need for heat dissipation in industrial production. Secondly, the combination of steel and aluminum materials makes the heat exchanger have good strength and corrosion resistance, and can adapt to harsh industrial environments. In addition, industrial steel aluminum fin tube heat exchangers have long service life and low maintenance costs, providing reliable guarantee for industrial production.

- Application fields of industrial extruded fin tube heat exchangers

Industrial extruded fin tube heat exchangers are widely used in various industrial fields due to their high efficiency and durability. In the chemical, petroleum, pharmaceutical and other industries, it is often used for heat dissipation of reactors, storage tanks and other equipment to ensure the stable operation of the production process. In industries such as electric power and metallurgy, industrial steel aluminum finned tube heat exchangers are used to cool equipment such as generator sets and steel-making furnaces to prevent equipment damage due to overheating. In addition, in light industrial fields such as food processing and papermaking, industrial steel aluminum finned tube heat exchangers also play an important role in ensuring the continuity of production lines and product quality.

- Installation and maintenance of industrial steel aluminum finned tube heat exchangers

The installation and maintenance of industrial steel aluminum finned tube heat exchangers are equally important. During the installation process, it is necessary to ensure that the location of the heat exchanger is properly selected to avoid being blocked or impacted by external objects. At the same time, it is necessary to strictly follow the drawings and instructions during installation to ensure that the connections are tight and the sealing is good. In terms of maintenance, the heat exchanger should be cleaned regularly to remove dust and dirt accumulated on the surface to maintain its good heat dissipation performance. In addition, it is also necessary to regularly check whether the pipes and connections of the heat exchanger are rusted or damaged, and if so, they should be repaired or replaced in time.

- Energy saving and environmental protection characteristics of industrial steel aluminum finned tube heat exchangers

The advantages of industrial steel aluminum finned tube heat exchangers in terms of energy saving and environmental protection are becoming increasingly prominent. Its efficient heat dissipation performance allows heat to be more fully utilized and reduces energy waste. At the same time, the recyclability of steel and aluminum materials also reduces the risk of environmental pollution. In addition, some advanced industrial steel aluminum fin tube heat exchangers also adopt intelligent control systems, which can automatically adjust the heat dissipation according to actual needs, further improving energy utilization efficiency.

- Development Trend of Industrial Steel Aluminum Fin Tube Heat Exchangers

With the advancement of science and technology and the development of industry, industrial steel aluminum fin tube heat exchangers will continue to develop in the direction of high efficiency, energy saving and environmental protection. In the future, we can expect more advanced manufacturing processes and materials to be used in the production of heat exchangers to improve their heat dissipation performance and durability. At the same time, with the development of intelligent technology, industrial steel aluminum fin tube heat exchangers will also achieve more intelligent control and management, providing more convenient and efficient heat dissipation solutions for industrial production.

In summary, industrial steel aluminum finned tube heat exchangers play an important role in industrial production due to their high efficiency, durability, energy saving and environmental protection. With the continuous advancement of technology and the expansion of application fields, industrial steel aluminum fin tube heat exchangers will usher in broader development prospects.