Internally finned tubes are a valuable component in heat exchanger systems

Internally finned tubes are a type of heat exchanger tubes that have fins on the inside surface. These fins are designed to increase the heat transfer efficiency of the tube by increasing the surface area available for heat exchange.

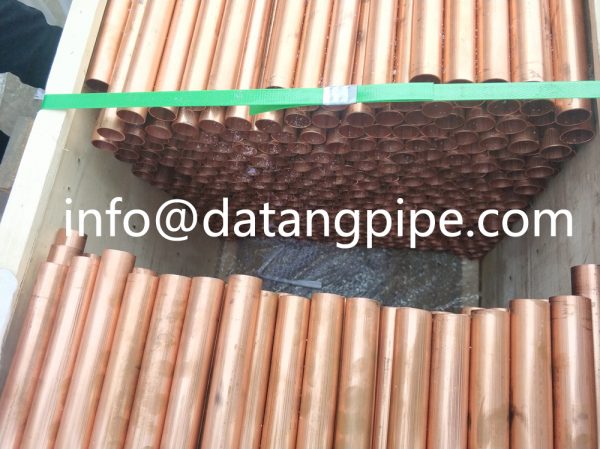

The fins on internally finned tubes are typically made of a high thermal conductivity material, such as copper or aluminum. They are attached to the inside surface of the tube using various methods, such as brazing or welding. The fins can be either straight or helical in shape, depending on the desired heat transfer characteristics.

One of the main advantages of internally finned tubes is their ability to enhance heat transfer in a compact space. By increasing the surface area available for heat exchange, the fins allow for a greater amount of heat to be transferred between the fluid flowing inside the tube and the surrounding environment. This is particularly useful in applications where space is limited, such as in air conditioning systems or refrigeration units.

Another advantage of internally finned tubes is their ability to improve the overall efficiency of a heat exchanger system. By increasing the heat transfer rate, the fins help to reduce the temperature difference between the fluid and the surrounding environment. This results in a more efficient heat exchange process, which can lead to energy savings and reduced operating costs.

Internally finned tubes are commonly used in a variety of industries, including HVAC (heating, ventilation, and air conditioning), power generation, and chemical processing. They can be found in a wide range of applications, such as heat exchangers, condensers, evaporators, and boilers.

In conclusion, internally finned tubes are a valuable component in heat exchanger systems. Their ability to increase heat transfer efficiency and improve overall system performance makes them a popular choice in various industries. Whether it is for cooling or heating purposes, internally finned tubes play a crucial role in optimizing energy usage and maintaining optimal operating conditions.