What are Helical Finned Tubes?

What are Helical Finned Tubes? Helical finned tubes are heat exchange elements that utilize spiral fins to enhance heat transfer. They are energy-saving heat transfer components for equipment such as boilers and pressure vessels. Their heat transfer area can reach several to dozens of times that of plain tubes. Manufacturing processes include high-frequency resistance welding, [...]

Basic Guide to Serrated Fin Tubes

Basic Guide to Serrated Fin Tubes Heat exchangers are complex devices that require a careful selection of tubes to achieve optimal heat transfer efficiency. Serrated finned tubes are becoming increasingly popular in various industries due to their unique design and ability to improve heat exchange processes. What Are Serrated Finned Tubes? Serrated finned tubes [...]

The Effect of Economizers on Boilers

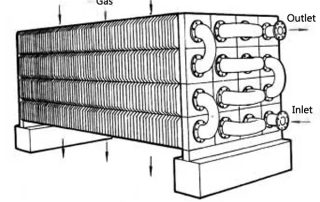

The Effect of Economizers on Boilers A boiler economizer is a highly efficient, energy-saving device widely used in industrial boiler systems. Its primary function is to utilize flue gas waste heat to raise boiler feed water temperature, reducing fuel consumption and thereby achieving energy conservation and emission reduction. What is a boiler economizer? A [...]

Difference Air Preheater and Economizer

Difference Air Preheater and Economizer Although both preheaters and economizers are devices used to improve boiler thermal efficiency, their operating principles and functions differ. Preheaters primarily heat condensate, reducing feedwater transportation power consumption; economizers utilize flue gas waste heat to heat air before it enters the boiler, thereby reducing flue gas emissions and improving [...]

Difference Studded Finned Tube and Fin Tube

Difference Studded Finned Tube and Fin Tube Studded Finned Tube is a tube with a nail-shaped body, while Finned Tube is a tube with a sheet-like shape. The two types of tubes have different applications. I. Basic Concepts of Studded Finned Tube and Finned Tube 1. What is a Studded Finned Tube? Studded Finned [...]

Energy Transfer Finned Tube Manufacturer and Supplier

Energy Transfer Finned Tubes for Heat Exchanger Finned tubes serve as a core component for enhancing heat transfer, achieving efficient energy exchange through structural design and material optimization. Their working principles and technical characteristics can be summarized as follows: I. Energy Transfer Finned Tube Energy Transfer Principles Extended Heat Transfer Area Finned tubes [...]

High-Frequency Welded Spiral Fin Tubes VS Serrated High-Frequency Welded Spiral Fin Tubes

High-Frequency Welded Spiral Fin Tubes VS Serrated High-Frequency Welded Spiral Fin Tubes The main differences between high-frequency welded spiral fin tubes and serrated high-frequency welded fin tubes are structural features, heat transfer performance, manufacturing process, resistance characteristics, and price. The main differences between high-frequency welded spiral fin tubes and serrated high-frequency welded fin tubes [...]

You Should Know Fin Tube Selection Guide

You Should Know Fin Tube Selection Guide How to choose the right fin tube for the heat exchanger? The key points of fin tube selection include material, fin spacing, fin height, fin spacing, fin shape, etc. Choose the appropriate material and structure according to the specific use situation to achieve better heat exchange [...]

6-meter High-frequency Welded Fin Tube Heat Dissipation Area

6-meter High-frequency Welded Fin Tube Heat Dissipation Area The heat dissipation coverage area of 6-meter high-frequency welded fin tubes is usually 60-120 square meters, depending on the fin specifications, heat medium type and use environment. High-temperature steam can improve heat dissipation efficiency, and good insulation conditions can be closer to the ideal value. Among [...]

What Are the Advantages of Using Spiral Finned Tubes?

What Are the Advantages of Using Spiral Finned Tubes? Spiral fin tubes are widely welcomed by users for their efficient heat transfer performance, compact structure, space saving, strong adaptability, good corrosion resistance, high strength, good reliability and low maintenance cost. 1. Efficient heat transfer performance The primary advantage of spiral finned tubes is their [...]

Why do Evaporators Use Low Finned Tubes?

Why do Evaporators Use Low Finned Tubes? Why Low-Fin Tubes Are Chosen for Evaporators The evaporator uses low-fin tubes mainly because of its excellent heat transfer performance and anti-deformation ability. Low-fin tubes significantly increase the surface area by processing spiral fins on the outer surface of the light tube, thereby improving the heat [...]

How to Choose G-type Fin Tube?

Here is the professional of the G-Type Finned Tube Selection Guide, optimized for technical accuracy and industry applicability: Issues to note when choosing G-type finned tubes: 1. The working pressure of the finned tube radiator should meet the working pressure of the system and comply with the current regulations of the relevant product manual; 2. [...]