The Effect of Economizers on Boilers

A boiler economizer is a highly efficient, energy-saving device widely used in industrial boiler systems. Its primary function is to utilize flue gas waste heat to raise boiler feed water temperature, reducing fuel consumption and thereby achieving energy conservation and emission reduction.

What is a boiler economizer?

A boiler economizer is a heat exchange device that utilizes flue gas waste heat to heat boiler feed water. Typically located at the tail end of a boiler’s flue, it absorbs heat from the flue gas to raise feed water temperature, thereby reducing fuel consumption and achieving energy conservation and emission reduction.

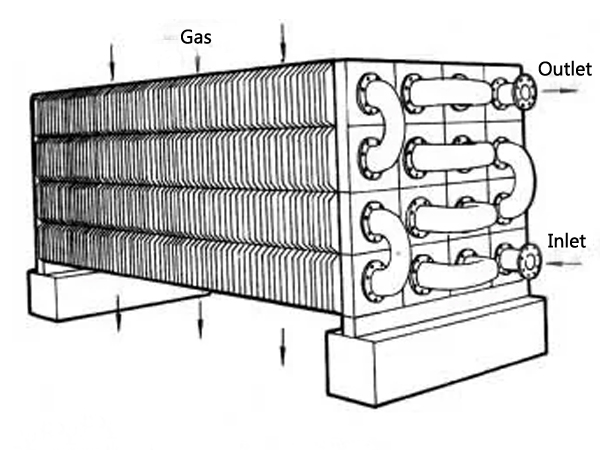

Power plant industrial boiler economizer

How a Boiler Economizer Works

A boiler economizer uses heat exchange to transfer waste heat from the flue gas to the boiler feed water. Specifically, flue gas enters the economizer from the tail end of the boiler and exchanges heat with the economizer tube bank connected in parallel with the boiler system. This heat exchange reduces the flue gas temperature and heats the boiler feed water. Once the heated feed water enters the boiler, it reduces fuel consumption and improves boiler efficiency.

Boiler Economizer Types

Boiler economizers can be categorized into various types based on their structure and installation location. Common types include horizontal, vertical, internal, and external. Horizontal economizers are simple and easy to install, but they occupy a larger area. Vertical economizers are compact and require less floor space, but are prone to ash accumulation. Internal economizers can be installed directly within the boiler, saving space but reducing boiler efficiency. External economizers allow for flexible placement but require additional piping.

Boiler Economizer Advantages and Disadvantages

The advantages of boiler economizers include: significantly reducing fuel consumption and improving boiler efficiency; reducing greenhouse gas emissions and benefiting the environment; reducing wear and corrosion in the boiler system; and increasing boiler feedwater temperature, reducing steam line losses. However, boiler economizers also have disadvantages: they increase initial investment costs; require regular maintenance and cleaning; are susceptible to ash accumulation and corrosion; and require a proper balance between flue gas volume and feedwater flow.

Boiler economizers can reduce flue gas temperature and calorific value, improving boiler thermal efficiency and saving fuel. The flue gas temperature at the superheater outlet is approximately 700°C. Even with a large number of convection tube bundles installed after the superheater, the flue gas temperature leaving the convection tube bundles remains as high as 250-350°C, due to the boiler water temperature being the saturation temperature at drum pressure. The flue gas still contains a significant amount of heat. Installing an economizer after the superheater or convection tube bundle effectively lowers the flue gas temperature, recovering significant heat and saving significant fuel. Because early boilers typically burned coal, they were called economizers.

Economizers can be classified in various ways, including the following:

Based on the degree of feedwater heating:

Embedded economizers can be classified into non-boiling and boiling types.

Based on manufacturing materials: There are cast iron and steel tube economizers. Non-boiling economizers are mostly made of cast iron, but can also be made of steel tubes, while embanked economizers can only be made of steel tubes. Cast iron economizers are mostly used in boilers with pressures less than 2.5 MPa. If the pressure exceeds 2.5 MPa, steel tube economizers should be used.

Based on the device type:

Vertical and horizontal types are available.

Based on the relative flow direction of exhaust gas and feedwater:

There are three types: co-current, counter-current, and mixed.

Based on the structural type:

Smooth tube economizers and finned economizers. Finned economizers include H-type economizers (commonly used) and spiral fin economizers.

Heat transfer can be categorized into two types:

Direct conduction and indirect conduction.

Direct conduction uses the boiler exhaust gas to directly radiate heat from the boiler water; indirect conduction uses a heat transfer medium to indirectly preheat the boiler water.