Project Description

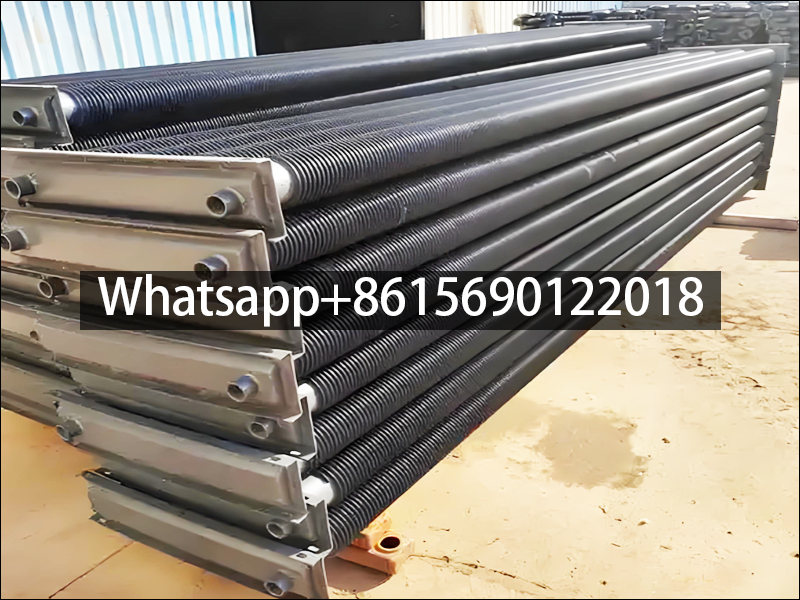

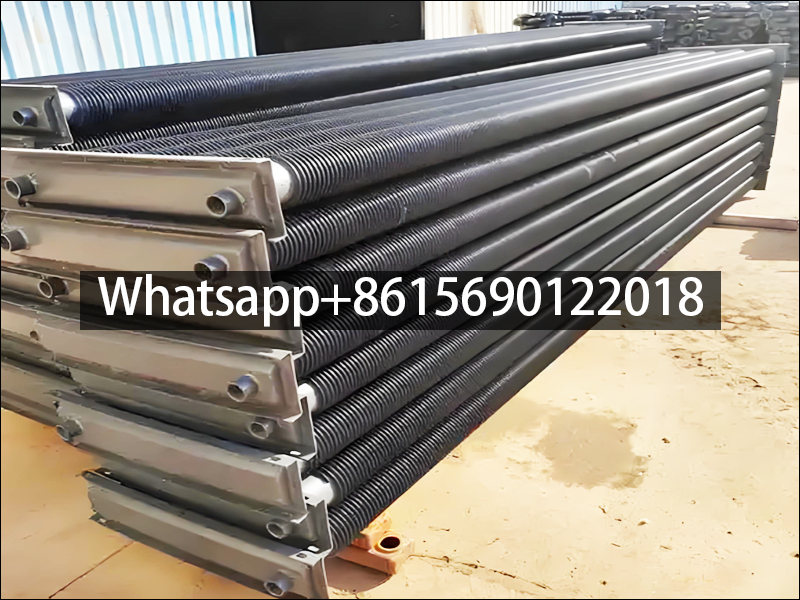

- Product Name: KL Finned Tube for Heat Exchanger

- Leave Your Message

Finned tube radiator is made of finned tubes, with efficient heat dissipation and precise temperature control, providing stable warmth for textile workshops, ensuring yarn quality and production efficiency, while being corrosion-resistant and durable, helping enterprises reduce costs and increase efficiency.

In the production environment of the textile industry, maintaining a suitable temperature plays a vital role in the smooth production process and the guarantee of product quality, and finned tube radiator has become a reliable choice for heating in the textile industry with its unique advantages.

Finned tube radiator has a simple and practical structure.

It is made of high-quality steel pipes with a diameter of 108, and multiple steel pipes are neatly arranged, with a simple and generous appearance. Although this structure seems simple, it has excellent heat dissipation capacity. When hot water or steam and other heat media are passed into the light exhaust pipe, the heat will be continuously dissipated to the surrounding through the pipe wall of the steel pipe, quickly raising the temperature in the workshop.

In a large space like a textile workshop, it can stably transmit warmth to every corner, avoid the situation of excessive local temperature difference, create a comfortable working environment for textile workers, and allow textile machines to operate stably under suitable temperature conditions.

For the textile industry, the production environment requirements are relatively strict, and it is necessary to maintain relatively stable and appropriate temperature and humidity.

The finned tube radiator can just meet this demand. It can accurately adjust the temperature and keep the temperature in the workshop in the most favorable range for textile production by controlling the flow of heat medium. For example, the appropriate temperature can ensure the toughness and softness of the yarn, reduce the undesirable phenomena such as broken ends and flying flowers, and improve the quality and production efficiency of textiles.

The finned tube radiator also has good durability.

There may be some fiber dust floating in the textile workshop, but its solid steel pipe material makes it have strong corrosion resistance and wear resistance. It can serve the textile workshop stably for a long time, reduce the trouble and cost caused by frequent maintenance and replacement, and provide strong guarantee for the stable production of the enterprise.

Finned tube radiators play an important role in the heating field of the textile industry due to their high efficiency in heat dissipation, precise temperature control, durability and stability, and help the continuous development of the textile industry.

Finned Tube Heat Exchangers in Textile Industry Applications

Introduction

The textile manufacturing process requires precise temperature control during fiber processing, dyeing, and drying operations. Finned tube radiators have become essential heat exchange components in modern textile plants due to their superior thermal efficiency and compact design.

Technical Advantages

1. Core Performance Parameters

ParameterSpecificationHeat Transfer Area5-12x bare tube (customizable fin density)Working Temperature50-300°C (steam/hot water systems)Pressure Rating1.6-4.0MPa (PN16-PN40 standards)Material CompositionCarbon steel/SS304/SS316 (anti-corrosion)

2. Operational Benefits

FeatureTextile Industry ApplicationRapid Heat-upReduces preheating time by 30-40%Uniform Temperature±2°C deviation in dyeing vatsSpace Efficiency60% smaller footprint than smooth tubesLow Maintenance5-8 year service life in humid conditions

Implementation Cases

In yarn drying chambers, finned tube arrays demonstrate 25% higher energy efficiency compared to conventional heating coils. The enhanced surface area (see Table 1) allows lower steam pressure (0.3-0.5MPa) while maintaining 85-90℃ chamber temperatures.

Conclusion

These radiators provide textile manufacturers with reliable thermal solutions that optimize energy consumption while meeting strict process temperature requirements. Their modular design enables flexible integration into existing production lines.