Project Description

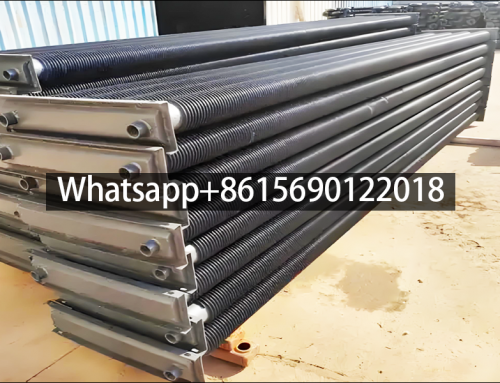

- Product Name: Steam Fin Tube Radiator

- Leave Your Message

Steam fin tube radiator is a fin tube radiator that uses steam as a heat transfer medium. It achieves the purpose of heating through the circulation of steam, with high heat exchange efficiency and a wide range of applications.

Steam fin tube radiators are usually made of steel pipe welding, and the material is generally low carbon steel or carbon steel. The equipment is light in weight and has moderate performance. Its heating temperature can reach about 180℃, the heat dissipation area is large, suitable for various places, and it is wear-resistant, durable and has a long service life.

The heat transfer medium of the steam fin tube radiator is high-temperature steam, which heats the air by circulating in the heat pipe, thereby increasing the indoor temperature. This radiator is widely used in various fields such as industry, chemical industry, agriculture, etc., and can be processed into different models according to actual needs to meet various needs.

The heat source of the steam fin tube radiator can be solar energy, liquefied gas, natural gas, etc., which has the characteristics of energy saving and low carbon.

Steam Finned Tube Radiators: Technical Overview

1. Steam Fin Tube Radiator Manufacturing Process

Steam finned tube radiators are manufactured through precision engineering processes:

- Tube Preparation: Seamless carbon steel tubes (ASTM A179) are cut to required lengths

- Fin Attachment: Fins are attached via:

- L-footing: For low-temperature applications (<200°C)

- Embedded: High-pressure resistance (up to 25 bar)

- G-footing: Corrosion-resistant variants

- Assembly: Tube bundles are assembled with headers using TIG welding

- Pressure Testing: Hydrostatic tested at 1.5x working pressure

- Surface Treatment: Hot-dip galvanizing or epoxy coating

2. Steam Fin Tube Radiator Key Characteristics

ParameterTypical ValueMeasurement StandardHeat Transfer Rate150-400 W/m²KISO 1217Operating Pressure0.5-16 barASME B31.1Temperature Range110°C-250°CEN 14336Fin Density157-433 fins/meterBS 3274Material GradeCarbon steel/SS304/SS316LASTM A213

Unique Features:

- 40-60% higher heat transfer than bare tubes

- Self-cleaning fin arrangement

- Modular design for easy maintenance

- Vibration-resistant construction

3. Steam Fin Tube Radiator Application Case Studies

A. Pharmaceutical Industry (Switzerland)

- Installation: 120kW unit for cleanroom temperature control

- Configuration: 4-row SS316L with 236 fins/meter

- Results: 22% energy savings vs. conventional heaters

B. Food Processing Plant (Canada)

- Application: Drying line heat recovery

- Parameters:

- Steam pressure: 8 bar

- Surface temp: 165°C

- Heat recovery: 3.2MJ/hour

C. District Heating (Norway)

- Project Scale: 850m of finned tubing

- Performance:

- Output: 12MW thermal power

- Efficiency: 94% at -15°C ambient

- Lifespan: 15+ years with minimal maintenance

4. Steam Fin Tube Radiator Maintenance Considerations

- Annual steam trap inspection

- Biannual fin cleaning (compressed air)

- 5-year pressure vessel recertification

- Recommended spare parts inventory: gaskets (20%), bolts (15%)