Shell and tube heat exchangers are used for oil/gas/chemical/food and beverage/pharmaceuticals

Shell and tube (tube shell) heat exchanger product classification:

Fixed tube plate heat exchanger

Floating head heat exchanger

U-tube heat exchanger

Double tube plate heat exchanger

Product structure:

Divided into single tube pass/double tube pass/multi-tube pass

Can also be customized according to customer needs

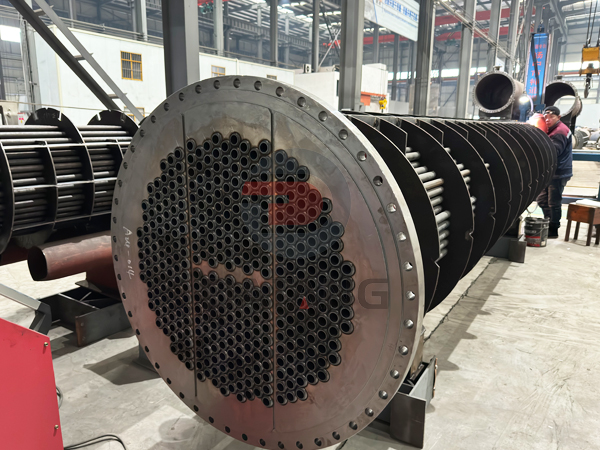

The shell and tube heat exchanger is a wall heat exchanger that uses the wall of the tube bundle enclosed in the shell as the heat transfer surface. This heat exchanger has a simple structure, low cost, wide flow cross-section, and is easy to clean scale; but the heat transfer coefficient is low and the floor space is large. It can be made of various structural materials (mainly metal materials), can be used under high temperature and high pressure, and is the most widely used type.

Shell and tube heat exchangers include fixed tube plate steam-water heat exchangers, shell and tube steam-water heat exchangers with expansion joints, floating head steam-water heat exchangers, U-shaped shell and tube steam-water heat exchangers, corrugated shell and tube steam-water heat exchangers, and segmented water-water heat exchangers. The main control parameters of shell and tube heat exchangers are heating area, hot water flow, heat exchange capacity, heat medium parameters, etc.

Product parameters

Fixed tube sheet heat exchanger

Fixed tube sheet heat exchanger specifications include: F = 1㎡-2150㎡, generally selected and designed according to the user’s process parameters.

OD 19mm Tube Shell Heat Exchanger Parameters

| Cylinder Diameter DN/mm | Nominal Pressure PN/MPa | Maximum Heat Transfer Area \(m^{2}\) / Heat Transfer Tube Length/mm |

| 159 | 0.6 – 6.4 | 1.3 (1500), 1.7 (2000), 2.6 (3000) |

| 219 | 0.6 – 6.4 | 2.8 (1500), 3.7 (2000), 5.7 (3000) |

| 273 | 0.6 – 6.4 | 5.4 (1500), 7.4 (2000), 11.3 (3000), 17.1 (4500), 22.9 (6000) |

| 325 | 0.6 – 6.4 | 8.3 (1500), 11.2 (2000), 17.1 (3000), 26 (4500), 34.9 (6000) |

| 400 | 0.6 – 6.4 | 14.5 (1500), 19.1 (2000), 30.1 (3000), 45.7 (4500), 61.3 (6000) |

| 500 | 0.6 – 6.4 | 19.8 (1500), 31.2 (2000), 47.6 (3000), 72.2 (4500), 96.8 (6000) |

OD 25mm Tube Shell Heat Exchanger Parameters

| Cylinder Diameter DN/mm | Nominal Pressure PN/MPa | Maximum Heat Transfer Area \(m^{2}\) / Heat Transfer Tube Length/mm |

|---|---|---|

| 159 | 0.6 – 6.4 | 1.2 (1500), 1.6 (2000), 2.5 (3000) |

| 219 | 0.6 – 6.4 | 2.7 (1500), 3.7 (2000), 5.7 (3000) |

| 273 | 0.6 – 6.4 | 4.2 (1500), 5.7 (2000), 8.7 (3000), 13.1 (4500), 17.6 (6000) |

| 325 | 0.6 – 6.4 | 6.3 (1500), 8.5 (2000), 13 (3000), 19.7 (4500), 26.5 (6000) |

| 400 | 0.6 – 6.4 | 10.8 (1500), 14.6 (2000), 22.3 (3000), 33.8 (4500), 45.4 (6000) |

| 500… | 0.6 – 6.4 |

U-tube heat exchanger

The specifications of U-tube heat exchanger are: F=1㎡-2150㎡, generally selected and designed according to the user’s process parameters.

OD 19mm U-tube Heat Exchanger Parameters

| Cylinder Diameter DN/mm | Nominal Pressure PN/MPa | Maximum Heat Transfer Area \(m^{2}\) / Heat Transfer Tube Length/mm |

|---|---|---|

| 325 | 0.6 – 6.4 | 6.7 (1500), 8.9 (2000), 13.4 (3000), 20.1 (4500), 27 (6000) |

| 400 | 0.6 – 6.4 | 13.4 (1500), 17.9 (2000), 26.9 (3000), 40.3 (4500), 54.5 (6000) |

| 500 | 0.6 – 6.4 | 22.3 (1500), 29.7 (2000), 44.6 (3000), 66.9 (4500), 90.5 (6000) |

| 600 | 0.6 – 6.4 | 46.1 (1500), 69.1 (2000), 103.6 (4500), 129.7 (6000) |

OD 25mm U-tube Heat Exchanger Parameters

| Cylinder Diameter DN/mm | Nominal Pressure PN/MPa | Maximum Heat Transfer Area \(m^{2}\) / Heat Transfer Tube Length/mm |

|---|---|---|

| 325 | 0.6 – 6.4 | 3 (1500), 4 (2000), 6 (3000), 9 (4500), 12.1 (6000) |

| 400 | 0.6 – 6.4 | 13.7 (1500), 18.6 (2000), 14.7 (3000), 43.1 (4500), 29.8 (6000) |

| 500 | 0.6 – 6.4 | 13 (1500), 17.4 (2000), 26.1 (3000), 39.1 (4500), 53 (6000) |

| 600 | 0.6 – 6.4 | 28.6 (2000), 42.9 (3000), 64.3 (4500), 87.2 (6000) |

Shell and tube condenser

| Specification \(m^{2}\) | Effective Length/mm | Outer Diameter/mm | Approximate Weight/kg |

|---|---|---|---|

| 2 | 1000 | 219 | 80 |

| 3 | 960 | 273 | 120 |

| 5 | 1600 | 273 | 200 |

| 10 | 2200 | 400 | 400 |

| 15 | 2100 | 500 | 550 |

| 20 | 2100 | 500 | 800 |