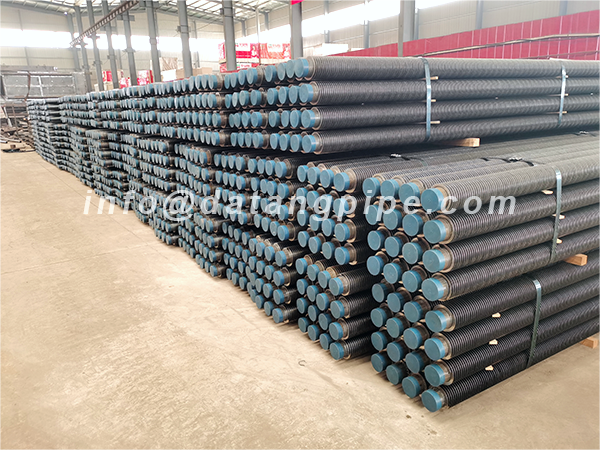

Spiral welded finned tubes for pepper drying equipment

Spiral welded finned tubes are based on precise structure and high-frequency welding technology to evenly transfer heat and ensure bright color and pure taste of dried peppers. Its efficient heat dissipation capacity shortens the drying time by 30%, adapts to various heat medium conditions, and can be stably operated from large processing plants to farmers’ equipment. It is easy to maintain and has become a key technical support for improving pepper quality and market competitiveness.

In the pepper drying operation, efficient and stable drying equipment is the key to ensuring the quality and yield of peppers, and high-frequency welded finned tubes play a pivotal role in it. With its unique design and excellent performance, it provides continuous and efficient heat support for the pepper drying process.

From the perspective of structural design

The spiral welded finned tubes used in pepper drying equipment are exquisitely constructed. As the core channel for the circulation of heat medium, the base tube is usually made of high-quality pipes with good strength and thermal conductivity. Strength ensures that it can withstand pressure during the circulation of heat medium and ensures stable transportation of heat medium; thermal conductivity enables the heat of heat medium to be quickly transferred to the surface of the base tube. The fins are closely arranged on the surface of the base tube and firmly combined with the base tube through high-frequency welding technology. The shape, spacing and arrangement of the fins are carefully designed. While increasing the heat dissipation area, the hot air flow path is optimized to evenly distribute the hot air in the drying equipment, ensuring that the peppers can be heated in all directions and evenly, avoiding local over- or under-drying.

High-frequency welding process is the technical core of this type of finned tube. During the welding process, the skin effect and proximity effect generated by the high-frequency current allow the contact part between the base tube and the fin to quickly heat up to the welding temperature, achieving a tight and uniform connection between the two. This welding method greatly improves the heat conduction efficiency, reduces thermal resistance, and enables the heat of the heat medium to be smoothly transferred from the base tube to the fin. When the heat medium flows in the base tube, the heat can be quickly dissipated to the surrounding air through the fins, providing sufficient heat for pepper drying, accelerating the drying process, and improving the drying efficiency.

In terms of performance advantages

Spiral welded finned tubes for pepper drying equipment perform excellently. Its efficient heat dissipation capacity can transfer a large amount of heat to the drying space in a short time, quickly increase the temperature in the drying equipment, and accelerate the evaporation of pepper water. Stable heat output ensures small temperature fluctuations during the drying process, which is conducive to ensuring the drying quality of peppers, making the dried peppers bright in color, good in taste, and pure in spiciness. Moreover, the finned tube can adapt to different heat medium conditions, whether it is high-temperature hot water, steam or hot air, it can efficiently transfer heat to meet the diverse heat requirements during the pepper drying process.

In the pepper drying process, high-frequency welded finned tubes play a key role. The uniform heat distribution makes the peppers uniformly heated in the drying equipment, avoiding the burning of peppers due to local overheating, or incomplete drying due to insufficient local temperature. The efficient heat dissipation performance shortens the drying time of peppers, reduces energy consumption, and improves production efficiency. The stable heat supply ensures the stability of the pepper drying quality. For large-scale pepper drying operations, it can effectively improve the overall quality of the product and enhance market competitiveness.

From the perspective of applicable scenarios

The spiral welded finned tubes for pepper drying equipment are suitable for all types of pepper drying equipment. Whether it is the industrial drying production line of a large-scale pepper processing plant, through a large-scale finned tube combination, it can meet the high-intensity drying needs; or the simple drying equipment used by small farmers, its compact structure and efficient performance can also provide reliable heat support for small-scale pepper drying.

In terms of maintenance

The high-frequency welded finned tube for pepper drying equipment is relatively convenient. Regularly check whether the fins are dusty, damaged or deformed. If there is dust, it can be cleaned in an appropriate way to ensure heat dissipation efficiency; check whether the base tube has leakage, corrosion, etc., and take anti-corrosion measures in time for minor corrosion. Due to its relatively simple structural design, maintenance personnel can easily inspect and repair each component to ensure the long-term stable operation of the equipment and reduce the interruption time of drying operations caused by equipment failure.

The spiral welded finned tube for pepper drying equipment has become the core component of pepper drying equipment with its unique structural design, advanced high-frequency welding process, excellent performance advantages, key role in pepper drying, wide application scenarios and convenient maintenance methods. It provides stable and efficient heat guarantee for pepper drying operations, strongly promotes the development of the pepper drying industry, and is a trustworthy key equipment component in the field of pepper drying.