Stainless Steel KL Finned Tube for Heat Exchanger

L/LL/KL Finned Tube Product Description:

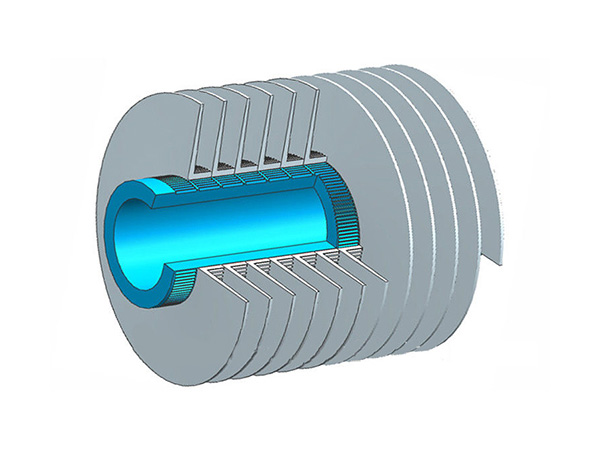

– KL Finned Tube(Knurled Aluminum Tubing)

Produced same like L-TYPE but before application of fins the surface of base tube is knurled. The fin foot is knurled into the knurling to get a higher bond between tube and fins, resulting in better heat transfer parameters.

Max. working temperature: 260°C

Fin Materials: Aluminium and Copper

Base Tube Materials: No limits

– L Finned Tube

The fin strip will be shaped in L form and tension wound to the base tubes outer surface. The L foot of the fin enhances the corrossion protection of the base tubes.

Max. working temperature: 150°C

Fin Materials: Aluminium and Copper

Base Tube Materials: No limits

– LL Finned Tube

Same way produced like L-TYPE but the fin foot is overlapping and covers the base tube outer surface which increases the corrossion protection of the base tube compared to the L-Type.

Max. working temperature: 180°C

Fin Materials: Aluminium and Copper

Base Tube Materials: No limits

L/LL/KL Finned Tube(Knurled Aluminum Tube) Manufacturing Process:

Applied Fin Tube is made with strip wrapped under tension around the base of the tube. Fins are welded to the base tube at the strip ends.

L/LL/KL Finned Tube(Aluminum Finned Tubes) Advantages:

– L Finned Tube

Suitable for low-temperature application.

The finning type is the most cost effective method compared to the others.

The failed fins can be easily removed during production and bare tube can be used again for finning.

There is no need for make a helical grove over the core tube.

It is possible to place the fins on a very thin-walled tube with is particularly desirable when using expensive alloys as core tube.

The tube can withstand a temperature of up to 130°C without the risk of atmospheric corrosion or thermal stress.

– LL Finned Tube

This type of finned tube is often used as an alternative to the more expensive extruded type fin in corrosive environments.

Maximum operating temperature 170ºC.

– KL Finned Tube

Corrosion-resistant Tubes

Vibration resistance

It can withstand temperatures of up to 320°C (608°F).

High thermal performance and stress resistance combined with protection from air corrosion is a one-of-a-kind combo.

Any form of finned tube can be replaced with KL

L/LL/KL Finned Tube Properties:

Atmospheric Corrosion Resistance: OK

Mechanical Resistance: Poor

Fin Contact: Interference Fit

Fin To Tube Bond :Moderate

Heat Transfer Efficiency :Moderate

L/LL/KL Finned Tube Applications:

. the petroleum, chemical and petrochemical process industries

. natural gas treatment

. the steel industry: blast furnace and converter systems

. power generation: steam turbine exhaust condensing

– contact condensing with cooling of circulating condensate

– fossil and nuclear power plants

. air conditioning (Freon, ammonia, propane)

. incineration of household refuse

. compressor coolers, etc.

L/LL/KL Finned Tube Specifications:

| Product Specification | ||

| Tube OD | 19~51 (mm) | 3/8”~2” |

| Tube Wall Thk | 1.65~3.0(mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.012”~0.02” |

| Fin Height | 10~16 (mm) | 0.394”~0.63” |

| Fin Pitch | 100~433 FPM | 3~11 FPI |

| Fin Type | L,LL,KL | |

| Material Combinations | ||

| Fin Material | Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) | |

| Copper | ||

| Tube Material | C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) | |

| S.S. (most common grade: TP304, 316) | ||

| Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi 90/10) | ||

| Titanium (most common grade: B338Gr2) | ||

| Applied Temperature |

L Type:150°CL,LL Type:180°C,kL Type:260°C | |

| Type of Service | L Type:Low temperature LLType:Low temperature, corrosive atmospheric environment applications KL Type:Medium temperature |

|

Product Description

Fin Type: L/LL/KL Finned Tube

Tube Material: Carbon steel, stainless steel, copper, aluminum

Fin Material: Copper, aluminum

Fin Tube Length: No Limit

Working temperature: 230℃.

Features: Adopting the winding process, the production efficiency is high, the lamella distance is uniform, the heat transfer is good, the finization ratio is high, the base tube can be protected from air erosion.

L/LL/KL Finned Tube

Finned tube is a tube with small finned fins around its outer surface. These fins act as a filter and a mechanism for transferring heat from the material inside the tube to or from the outer space. Finned tubes are used in applications where heat is transferred from a hot fluid to a cooler fluid through the wall of the tube. The rate at which this heat transfer occurs depends on three factors:

The difference in temperature between the two fluids.

The coefficient of heat transfer between each fluid and the wall.

Surface area of fluid exposure.

L type finned tube:

Adopting the winding process, the production efficiency is high, uniform lamella distance , good heat transfer, high finization ratio, the base tube can be protected from air erosion. The aluminum fin or copper fin is folded into an L shape and continuously spirally wound on the outer surface of the base tube under the action of tension.

Maximum working temperature-150°C (302°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper.

LL type finned tube:

Under the L-shaped foundation, the fin root completely covers the outer surface of the base tube; to some extent, this fin type guarantees better corrosion resistance. Maximum working temperature-180°C (356°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper

KL type finned tube:

Before the fins are continuously wound on the surface of the steel pipe, the outer surface of the base pipe needs to undergo a knurling process; after the fins are wound, the root of the fin attached to the steel pipe will also be knurled to strengthen the steel pipe and Combination of fins. For this reason, this fin type ensures better heat transfer characteristics under the fins of L and LL. Maximum working temperature-260°C (500°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper.

L/LL/KL Finned Tube Applications

Datang used in air coolers in petrochemical, electric power, paper making, tobacco, building heating and other industries, air heaters and air heaters in spray drying systems such as vegetable protein and starch in the food industry. Blast furnace and converter systems, power generation: condensate exhaust gas discharged from steam turbines, condensate contact cycle cooling condensation, fossil and nuclear power plants, air conditioners (Freon, ammonia, propane), waste incineration equipment, compressor coolers, etc.

We customized finned tube according to customer indivisual requirement, for more details about L/LL/KL finned tube please inquire us!

Frequently Asked Questions (FAQ) About L/LL/KL Finned Tube:

- What is a fin tube?

A fin tube, whether baseboard or convector-style, is a heating element, made of copper or steel, for a piping system. It has square or spiral aluminum “fins” that radiate (distribute) the heat and are low to the floor. Fin tubes replaced radiators in the 1940s and 50s and were popular before forced air systems became common.

- Why use finned tubes?

Finned tubes are used in applications involving the transfer of heat from a hot fluid to a colder fluid through a tube wall. The rate at which such heat transfer can occur depends on three factors: (1) the temperature difference between the two fluids; (2) the heat transfer coefficient between each of the fluids and the tube wall; and (3) the surface area to which each fluid is exposed. In the case of a bare (unfinned) tubes, where the outside surface area is not significantly greater than the inside surface area, the fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of fluid outside the tube (for example steam inside and oil outside), the overall heat transfer rate can be greatly improved by increasing the outside surface of the tube. In mathematical terms, the product of heat transfer coefficient for the outside fluid multiplied by the outside surface area is made to more closely match the product of the inside fluid heat transfer coefficient multiplied by the inside surface area.

So the whole concept of finned tubes is to increase the outside surface area of the tube. As an example, a finned tube configuration of 2” (nominal, 2.375” actual) pipe with a ¾” high welded helical solid fin of 12 gauge thickness with 6 fins per inch has an outside surface area of 8.23 sq. ft. per linear foot; whereas the same bare pipe has an outside surface area of only .62 sq. ft. per linear foot. That is a 13X increase in outside surface area.

By increasing the outside surface area of the tube, the overall heat transfer rate is increased, thereby reducing the total number of tubes required for a given application. This reduces the overall equipment size and the cost of the project. In many cases, one finned tube replaces six or more bare tubes at less than 1/3 the cost and ¼ the volume.

- What is Tension Wound Fin Tubes?

The Tension Wound Fin means the fins wrapped tightly around the tube and welded or stapled at the ends of tubes to hold the form. Tension Wound Fins can also be solder-coated to strength the corrosion resistance. Tension wound fin works especially prefer with fins and tubes that are use the same material.

There are 4 types of tension wound fin tubes in our factory:

- L finned tube

- LL finned tube

- KL finned tube

- Crimped finned tube

- How are L/LL/KL finned tubes made?

L finned tube:

The extruded fin tube is wrapped around the tube and secured at each end to provide some surface protection. L Fin tubes are renowned for maximum heat transfer and enhanced corrosion protection – suiting moderate temperature cooling applications.

LL finned tube:

The fin is wrapped around the tube with an overlapping foot and secured at each end. It offers excellent corrosion resistance and is often used as an alternative for expensive extruded fins in corrosive environments.

KL finned tube:

The KL finned tube is manufactured like the ‘L fin’ only the fin is wrapped around the tube and the foot is rolled into the outer surface of the preknurled tube. KL finned tubes give good surface protection to the tube and improve heat transfer.

- Where are L/LL/KL finned tube used?

. the petroleum, chemical and petrochemical process industries

. natural gas treatment

. the steel industry: blast furnace and converter systems

. power generation: steam turbine exhaust condensing

– contact condensing with cooling of circulating condensate

– fossil and nuclear power plants

. air conditioning (Freon, ammonia, propane)

. incineration of household refuse

. compressor coolers, etc.

- How do you ensure a quality product?

We always put quality as the most important thing for customers, and we control the quality from raw material inspection, production checking to water pressure test and strength test. Also the third party can be authorized to check.

Incoming inspection report for bare tube & strip.

Mill test certification for bare tube

Mill test certification for fin

Mill test certification for finned tube

Finned tubes dimension & visual inspection reports