The welding methods of fin tube mainly include high-frequency welding and laser welding

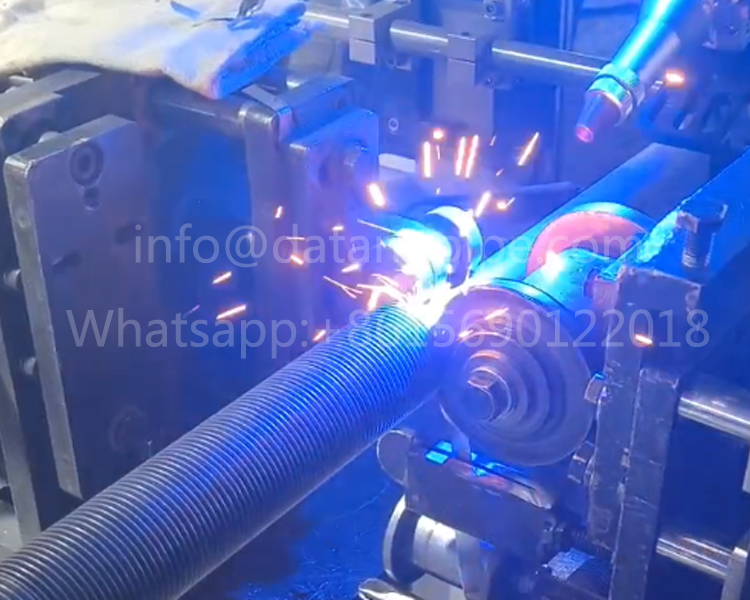

High-frequency welding is a commonly used finned tube welding method, which is characterized by high connection strength and good sealing. It is suitable for radiator installation in harsh environments such as high temperature and high pressure. High-frequency welded spiral finned tubes are one of the most widely used spiral finned tubes. They are now widely used in waste heat recovery in the power, metallurgy, cement industries, and petrochemical industries.

High frequency welding fin tube machine welding method-finned tube suppliers Datang

In the process of high-frequency welding, a firm connection is achieved by welding the pipe section with the fin or other components. This welding method not only has the advantages of high connection strength and good sealing, but also is suitable for radiator installation in harsh environments such as high temperature and high pressure. However, the high-frequency welding process requires professional skills and equipment, and improper operation may lead to unstable welding quality and even cause safety accidents. Therefore, when performing high-frequency welding butt joints, it should be ensured that the operator has the corresponding qualifications and experience, and strictly follows the welding process requirements.

In addition, the docking method of finned tube radiators also includes other forms, such as flange connection and threaded connection, but high-frequency welding occupies an important position in the production and application of finned tubes due to its unique advantages.

Laser welding mainly relies on high-energy-density laser beams as heat sources, and achieves welding by the heat generated by the focused laser beam bombarding the weldment. The characteristics of this welding method include low heat input, small welding deformation and no influence from electromagnetic fields, which is particularly suitable for welding of micro parts and hard-to-reach parts.

Laser welded finned tube machine welding method-fin tube manufacturing company Datang

Although some materials may mistakenly describe it as a “type of pressure welding”, in fact, laser welding belongs to a type of melting welding and thermal cutting, and does not involve the use of pressure for welding

Laser welded fin tubes are fin tubes that use advanced laser welding technology. It has many significant advantages, making it popular in heat exchanger design.

The main advantages of laser welded fin tubes include:

Material cost savings: The base tube thickness can be 0.8-1.5 mm, and the fin thickness can be 0.3-1 mm. This flexibility greatly saves material costs.

High penetration rate: It can prevent gap corrosion, prolong service life, and reduce heat transfer resistance.

Break through material limitations: It can be processed with different materials, which further broadens its application range.

Easy for secondary processing: It can be directly coiled and bent to meet different production needs.

Small welding heat affected zone: Small metallographic changes make it possible to process small diameter finned tubes.

The laser welded fin tube welding method has the advantages of small heat affected zone, fast welding speed, and high weld quality. These characteristics make the laser welded finned tube perform well in heat exchange efficiency and heat transfer performance. In addition, laser welding technology has also broken through material limitations and can be processed with different materials, further broadening its application range. The application of laser welding machines is not limited to heat exchanger finned tubes, but also shows wide application potential in many fields, including high-precision welding, high penetration rate, easy automation, high flexibility, fast welding speed and stable welding quality.