What Are the Aadvantages of High Frequency Welded Spiral Fin Tubes Compared With Other Types of Fin Tubes?

High-frequency welded spiral fin tubes stand out with their advantages such as firm welding, efficient heat exchange and low cost. They have high weld strength, low thermal resistance, and heat exchange efficiency that can reach several times that of light tubes. In addition, automated production greatly reduces manufacturing costs, making them an ideal choice for harsh working conditions and efficient heat exchange.

Compared with other types of fin tubes, high-frequency welded spiral fin tubes have many advantages in welding strength, heat exchange efficiency, and processing costs. The following is a detailed introduction:

I. Welding quality and strength

—Firm welding:

High-frequency welding uses the skin effect and proximity effect of high-frequency current to quickly heat the fins and the surface of the base tube to a plastic state or melt, and achieves welding under pressure, with a firm weld and high welding strength.

Compared with some fin tubes that use mechanical connection or bonding, such as winding fin tubes, the fins of high-frequency welded spiral fin tubes are not easy to fall off, can withstand higher pressure and thermal stress, and are suitable for various harsh working conditions.

—Good weld quality:

high-frequency welding has a fast speed, a small heat-affected zone, a strong self-cooling effect on the weldment, excellent weld structure and performance, and is not prone to welding defects such as pores and slag inclusions, ensuring the overall quality and reliability of the finned tube.

II. Heat exchange performance

—Efficient heat exchange:

The structural design of the spiral fins greatly increases the surface area of the finned tube, and the welding between the fins and the base tube is tight, with low thermal resistance. Heat can be efficiently transferred from the base tube to the fin surface and then to the surrounding medium. Compared with the light tube, its heat exchange efficiency can be increased several times.

Compared with other types of finned tubes such as sleeve-type finned tubes, the fins of high-frequency welded spiral finned tubes are more tightly combined with the base tube, there is no gap thermal resistance, and the heat exchange effect is better.

—Enhanced heat transfer:

The shape and arrangement of the spiral fins can promote the turbulence of the fluid, reduce the thermal resistance of the boundary layer, and further improve the heat exchange efficiency. Under the same flow rate and temperature difference conditions, high-frequency welded spiral finned tubes can transfer more heat, which helps to achieve miniaturization and high efficiency of equipment.

III. Manufacturing process and cost

—High production efficiency:

High frequency welding is a welding process with a high degree of automation, fast welding speed, continuous production and high production efficiency.

Compared with some finned tubes with manual welding or complex assembly processes, high frequency welded spiral finned tubes have a short production cycle and can meet the needs of large-scale production.

—Low cost:

Due to high production efficiency and no need for a large amount of manpower and complex equipment, the manufacturing cost of high frequency welded spiral finned tubes is relatively low. At the same time, its efficient heat exchange performance makes the required pipe and fin materials relatively small under the same heat exchange requirements, which also reduces the material cost.

IV. Scope of application

—Various materials:

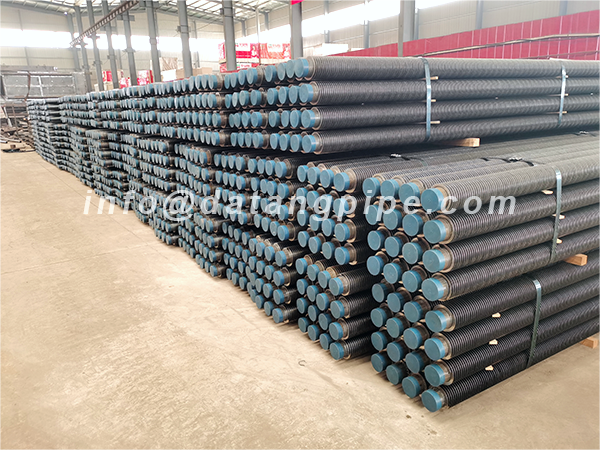

High frequency welded spiral finned tubes can use base tubes and fin materials of various materials, such as carbon steel, stainless steel, alloy steel, copper, aluminum, etc., and can choose suitable materials according to different use environments and medium requirements, with wide applicability.

For example, stainless steel or copper finned tubes can be used in corrosive environments, and alloy steel finned tubes can be used in high temperature environments.

—Flexible specifications:

High-frequency welded spiral fin tubes of different specifications can be produced according to actual needs, including different tube diameters, fin heights, fin spacing, etc.

It can meet the design requirements of various heat exchange equipment. Whether it is a large industrial heat exchanger or a small civilian heat exchanger, you can choose a high-frequency welded spiral fin tube of appropriate specifications.