What are the on-site detection methods for extruded finned tubes?

What are the on-site detection methods for extruded finned tubes?

The processing technology of extruded finned tubes is to process aluminum tubes and steel tubes into bimetallic composite tubes first, and then form fins after mechanical cold rolling.

Using the physical properties of aluminum tubes, finned tubes with steel tubes as the core and cold-rolled aluminum fins are made into a tight combination.

Extruded finned tubes have the following characteristics:

1. High heat transfer performance and low contact thermal resistance;

2. The contact area between the fins and the tubes is large, and the fit is tight and reliable;

3. Good corrosion resistance and stable performance in long-term use;

4. The fins have good rigidity and are not easy to deform.

Widely used in steel, petroleum, chemical, machinery, shipbuilding, power stations, hospitals and food industries.

What are the on-site detection methods for extruded finned tubes?

1. Before on-site detection, measure the delay time t from the acoustic wave monitor to the receiving system. And calculate the sound time correction value.

2. During measurement, the transmitting and receiving probes need to be raised and lowered synchronously at the same elevation or with a fixed height difference.

3. The measurement point distance of the extruded finned tube is 40cm, and it will be increased to 20cm when abnormalities are found.

4. To some extent, select its appropriate transmitting voltage and amplifier gain, and keep it unchanged during the test.

5. The extruded finned tube will display and record the time course curve of the received signal in real time to some extent.

6. Combine multiple extruded finned tubes into two test sections and test multiple sections separately.

7. After the side test of each group of test tubes is completed, the test points should be randomly sampled 10 times, and the relative standard deviation of the sound time should not be greater than 5%; the relative standard deviation of the amplitude should not be greater than 10%.

Packing: Plywood Case with Steel Frame

Mark: Standard+Steel Class+Size+calories+batches

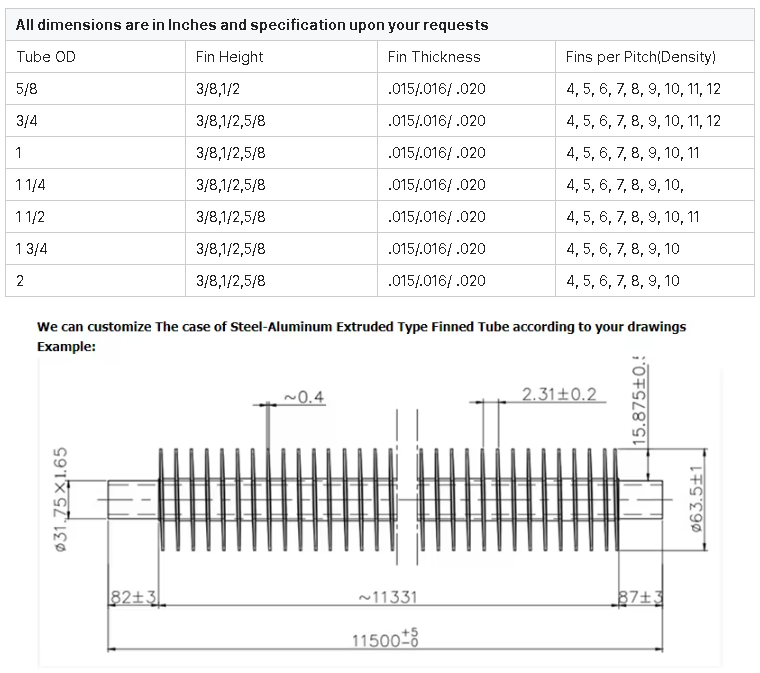

We can customize the size:

Extruded Finned Tube

Tube Material:Carbon Steel,Stainless Steel,Alloy Steel, Aluminum,Copper

Fin Material: Aluminum, Copper

Tube OD:10-51mm

Tube Thk:1.65-3.0mm

Fin Thk:0.3-1.2mm

Fin Pitch:2.0-15.0mm

Fin Height:5-16mm

Minimum order quantity: 1 piece

1 piece is also wholesale price

For more information, please contact us

Email:info@datangpipe.com

Whatsapp/Wechat:+8615690122018

Website:www.datangfintube.com