What is a spiral welded fin tube?

A spiral welded fin tube is a heat dissipation component that reduces the heat transfer resistance of the radiator by winding a steel strip around the steel tube, thereby improving the heat dissipation efficiency.

Helical Fin Tubing,welded fin tubes,helical finned tube,high fin tube,spiral fin tube heat exchanger

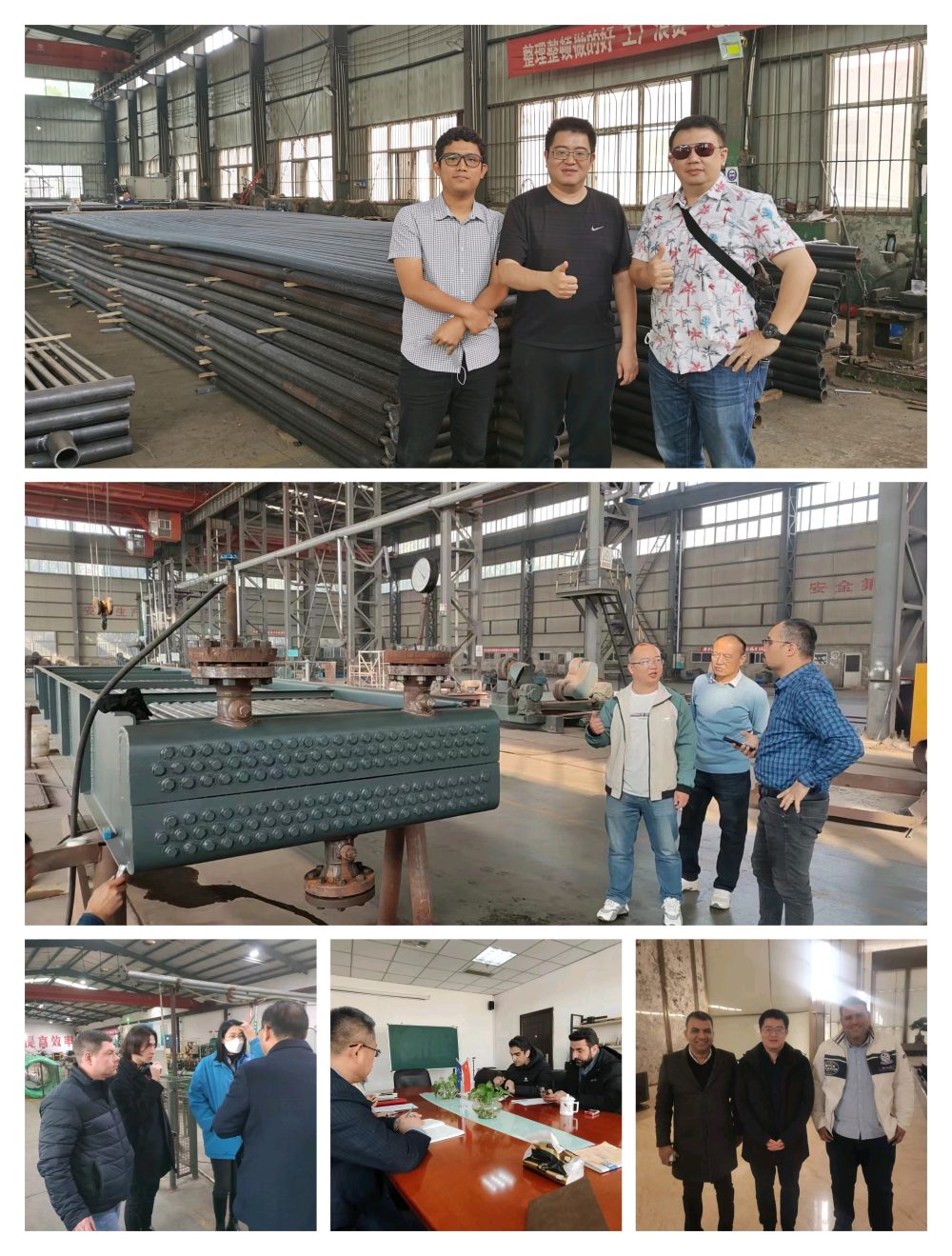

Fin tube Inspection Packing-Datang Fin Tube

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as

required

Its heat exchange area is many times or even dozens of times that of a bare tube. Most of them are made of seamless steel tubes or seamed steel tubes, and some are also wound with aluminum tubes. Aluminum tubes have higher heat dissipation efficiency, but the cost will also increase. In actual use, more users choose to wind with steel tubes.

Spiral fin tubes can adapt to different environments and are widely used in agriculture, industry, chemical industry and food industry.

In agriculture, it can provide a reasonable growth environment for plants; in industry, it can provide comfort for people in the workshop.

In addition, the installation time of spiral fin tubes is short, the length of the fin tubes in the equipment is about 6 meters, the contact points are reduced during installation, the installation is convenient, and it can withstand a certain amount of pressure, so it has a longer life in terms of use.

The processing technology of spiral welded finned tubes is simple and the materials are convenient. It is a spiral finned tube formed by directly winding a steel strip or an aluminum strip around a steel tube with mechanical force. It is currently widely used and can be processed into stainless steel sheets, aluminum sheets, carbon steel sheets, etc. It is generally wound into a spiral finned tube, which can also be called a winding finned tube.

Spiral finned tubes have been widely used in various boilers. Spiral finned tubes can be manufactured by a variety of methods. The finned tubes used in heat exchange equipment such as boilers and pressure vessels mainly have the following manufacturing methods: high-frequency resistance welded spiral finned tubes, brazed spiral finned tubes and integral spiral finned tubes.

This kind of tube has many fins processed on the original tube surface (both the outer surface and the inner surface), which expands the original surface and forms a unique heat transfer element.

The heat dissipation efficiency of steel spiral finned tubes can be 3 to 5 times that of ordinary light tubes. Due to its good heat dissipation effect, it is the choice of more and more consumers.

HG/T 3181-1989 “High-frequency resistance welded spiral fin tube” stipulates: The total length of the actual weld is not less than 90% of the total length of the fin, and the average width of the weld is not less than 80% of the fin width.

The actual welding rate of high-frequency resistance welded spiral fin tubes can reach 90%-95%, and the welding rate of brazed spiral fin tubes is slightly higher than that of high-frequency welding, but the welding rate is not easy to check.

The integral spiral fin tube does not have the problem of fin welding, and does not need to check the welding rate.

Customer factory inspection-Datang Fin Tube