What is high-frequency welded spiral fin tube?

High-frequency welded fin tube is one of the spiral fin tubes.

High-frequency welded fin tube is a fin tube made by high-frequency current welding technology, which is mainly used to improve heat exchange efficiency. High-frequency welded fin tubes heat the outer surface of the steel strip and steel tube through the skin effect and proximity effect of high-frequency current, and then complete the welding under a certain pressure, so that the base tube and the fin are basically integrated.

Structural characteristics of high-frequency welded spiral fin tube

High-frequency welded fin tubes are mainly composed of steel tubes and fins. Steel tubes are usually made of high-quality carbon steel or stainless steel, with good strength and corrosion resistance; fins are mostly made of aluminum, copper or other metals with excellent thermal conductivity, which can quickly transfer heat. This unique structural design greatly increases the heat exchange area, allowing heat to be exchanged on a larger surface area, significantly improving the heat exchange efficiency.

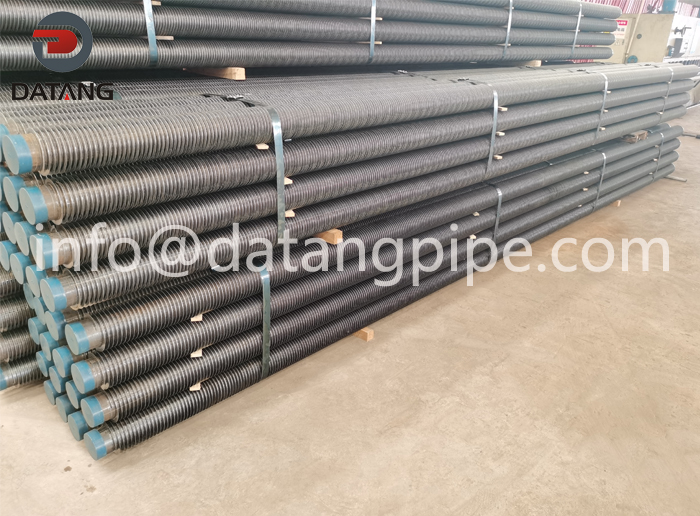

spiral fin tube

High-frequency welded helical finned tube performance characteristics

Efficient heat dissipation:

High-frequency welded finned tubes can significantly improve the heat dissipation efficiency. Compared with the base tube without welded fins, its heat dissipation efficiency can be increased by about 3-7 times.

Flexible customization:

It can be processed into finned tubes of different lengths and sizes according to user needs to meet the use requirements of different occasions.

Corrosion resistance:

Due to the advanced welding process, high-frequency welded finned tubes have good corrosion resistance and can extend the service life.

Strong adaptability:

High-frequency welded finned tube radiators can be used in steam, water and thermal oil heating systems, with high adaptability and low thermal resistance.

High-frequency welded finned tube application field

High-frequency welded finned tubes are widely used in various occasions requiring efficient heat exchange, such as chemical, food, textile, papermaking and other industries.

In drying equipment, high-frequency welded finned tubes have become the core heat exchange elements in the drying process with their advantages of efficient heat transfer, compact structure and corrosion resistance.

In workshop heating, high-frequency welded finned tubes greatly increase the heat dissipation area through high-frequency welding technology, which can release more heat in the same space, effectively solving the problem of insufficient and uneven heat distribution in large space heating.

Power industry:

In thermal power generation, nuclear power, geothermal power generation and other power stations, it is used for heat dissipation, insulation and cooling of various thermal equipment and pipelines.

Industrial waste heat recovery:

In industrial fields such as steel, metallurgy, petrochemicals, etc., waste heat resources in flue gas and exhaust gas are recovered for heating, hot water supply, etc.

Agricultural drying:

Applied to the drying process of materials such as grain, tobacco, and pulp, providing sufficient heat and improving drying efficiency.

Air conditioning and refrigeration:

As a heat transfer element of condenser and evaporator, it realizes heat exchange between refrigerant and air.

Shipbuilding industry:

Used for heat dissipation and insulation of ship thermal equipment, such as diesel engines, boilers, distiller, etc.

New energy utilization:

In the field of new energy such as solar energy and geothermal energy, heat energy is converted into electrical energy or directly used to improve the utilization rate of new energy.

Finned tubes are heat exchange tubes that are usually made by adding fins to the surface of the heat exchange tube to increase the outer surface area (or inner surface area) of the heat exchange tube, thereby achieving the purpose of improving the heat exchange efficiency.

High-frequency welded spiral finned tubes are made by using the skin effect and proximity effect of high-frequency current to heat the outer surface of the steel strip and the steel tube until the steel strip is in a plastic state or melted while the steel strip is wrapped around the steel tube, and the welding is completed under a certain pressure of the wrapped steel strip. This high-frequency welding is actually a solid phase welding.

Compared with methods such as inlaying, brazing (or overall hot-dip galvanizing), high-frequency welded spiral finned tubes are more advanced in terms of product quality (the welding rate of the fins is high, up to 95%), productivity and automation.

High-frequency welding

High-frequency welding (high-frequency welding) uses solid resistance heat as energy. During welding, the resistance heat generated by high-frequency current in the workpiece is used to heat the surface of the workpiece welding area to a molten or near plastic state, and then the forging force is applied (or not applied) to achieve the metal bonding. Therefore, it is a solid phase resistance welding method.

High frequency welding can be divided into contact high frequency welding and induction high frequency welding according to the way high frequency current generates heat in the workpiece. In contact high frequency welding, high frequency current is transmitted to the workpiece through mechanical contact with the workpiece. In induction high frequency welding, high frequency current generates induced current in the workpiece through the coupling effect of the induction coil outside the workpiece. High frequency welding is a highly specialized welding method, and special equipment should be equipped according to the product. It has high productivity and the welding speed can reach 30m/min. It is mainly used for welding longitudinal seams or spiral seams when manufacturing pipes.

The two major effects of high frequency current in high frequency welding are:

Skin effect-when the conductor is passed with alternating current, the current distribution on the conductor section is uneven, the current density gradually increases from the center of the conductor to the surface, and most of the current flows only along the surface of the conductor. A physical phenomenon. The lower the resistivity of the conductor, the greater the magnetic permeability, and the higher the frequency of the current, the more significant its skin effect.

Proximity effect-when the high frequency current flows in opposite directions in two conductors or in a reciprocating conductor, the current will be concentrated on the adjacent side of the conductor.

The current frequency range commonly used in high-frequency welding is 300-450kHz, and sometimes a frequency as low as 10kHz is used.

Characteristics of high-frequency welded finned tubes

1. Due to the fast welding speed and strong self-cooling effect of the weldment, not only the heat-affected zone is small, but also it is not easy to oxidize, so the structure and performance of the weld are very good.

2. Anti-corrosion performance, wear resistance, low contact thermal resistance, high stability, and anti-ash accumulation ability.

3. Large heat exchange area.

Types of high-frequency welding

High-frequency welding is divided into high-frequency resistance welding and high-frequency induction welding.

① High-frequency resistance welding:

Use rollers or contacts as electrodes to introduce high-frequency current into the workpiece. It is suitable for continuous longitudinal seam welding and spiral lap seam welding of pipes, welding of boiler fin tubes and spiral fins of heat exchangers. The outer diameter of the weldable pipe is 1200 mm and the wall thickness is 16 mm. The belly pole thickness of the I-beam can be welded 9.5 mm, and the productivity is very high.

② High-frequency induction welding:

Use an induction coil to heat the workpiece, and can weld small-diameter tubes with an outer diameter of 9 mm and thin-walled tubes with a wall thickness of 1 mm. It is often used for longitudinal seam welding of small and medium-sized diameter steel pipes and brass pipes, and can also be used for circumferential seam welding, but the power loss is greater than that of high-frequency resistance welding.

The main parameters affecting the quality of high-frequency welding are the frequency, power, workpiece forming angle, extrusion force, distance between the electrode (or induction coil) and the extrusion roller, and welding speed of the high-frequency power supply. The main equipment includes high-frequency power supply, workpiece forming equipment and extrusion mechanical device.

High-frequency welding has stable quality, high productivity and low cost. It is suitable for high-efficiency automatic production lines and is an advanced method for producing seamed tubes.

High-frequency welded fin tube manufacturing process

The manufacturing process of high-frequency welded fin tubes mainly includes steps such as raw material preparation, strip processing, welding forming, fin processing, inspection and packaging. Among them, welding forming is the core link, and parameters such as welding temperature, pressure, and time need to be strictly controlled to ensure welding quality and efficiency.

High-frequency welded fin tube price and market

The price of high-frequency welded fin tubes varies depending on factors such as material, specification, and manufacturer. There are many brands and models of high-frequency welded fin tube products on the market, with prices ranging from a few yuan to dozens of yuan. At the same time, with the continuous advancement of technology and the continuous expansion of application fields, the market demand for high-frequency welded fin tubes is also increasing.

High-frequency welded fin tubes are widely used in many fields due to their high efficiency, corrosion resistance, and easy customization, and continue to grow and develop with the increase in market demand.

Datang fin tube product’s specification outside diameter from 18 mm to 273 mm finned tube, The process includes high-frequency welded fin tubes, extruded fin tubes, L / L L / K L fin tubes, G -type Embedded fin tubes, low fin tubes, inner fin tubes, elliptical fin tubes, longitudinal fin tube,H type fin tube, the annual capacity can reach 100,000 tons.

We have professional engineer support, high efficiency sales team and competitive price superiority.

Our R & D department provides the strong technical support and enables us to receive some, O D M projects, and can provide you with drawings, design plans and thermal calculations, service has exceeded more than 3000 enterprises.

If you need finned tubes, contact us! Email:info@datangpipe.com,Whatsapp:+86 15690122018