Extruded finned tubes, 15 rolling composite finned tube machines, daily productivity 10,000 meters

Extruded finned tubes, also known as bimetallic rolled finned tubes, bimetallic rolled finned tubes are tubes that can withstand corrosion and completely overcome the shortcomings of L-shaped coiled tubes. The inner and outer tubes of the bimetal rolled sheet tube can be selected separately, and the inner tube can be selected according to the corrosion condition and pressure of the hot fluid, such as carbon steel, stainless steel, alloy steel, brass, etc. The outer tube can be made of metal with good ductility, strong ability to withstand atmospheric corrosion, and good heat transfer performance. Generally, aluminum and copper are used. After rolling, the inner and outer tubes can be completely tightly combined. In addition to the highly corrosive fluid in the tube, the bimetallic rolled sheet tube can also be used in wet air coolers to resist corrosion on the outside of the tube. The advantages are good corrosion resistance, long service life, high heat transfer efficiency, small pressure drop, high integrity and rigidity of the fins, because the fins are firm, not easy to deform, and can be cleaned with high-pressure water.

Steel Aluminum extruded finned tube

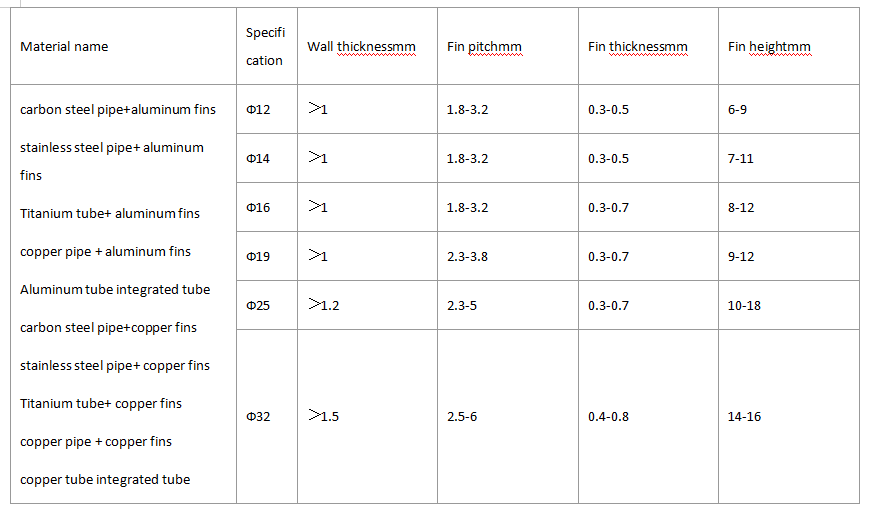

Dimensions and parameters of bimetal composite pipe processing:

Aluminum extruded finned tube is a processing form of finned tube, which is rolled from aluminum tube and steel tube or stainless steel tube (copper tube), with optimal material, energy saving and environmental protection, good heat dissipation effect, safe and durable, high temperature resistance, High efficiency and low energy consumption.

Copper Aluminum extruded finned tube

Aluminum extruded finned tubes have no burrs, no wrinkles, tight bonding, small thermal resistance, good heat transfer performance, high strength, small flow loss, no late deformation under long-term cold and hot conditions, and long working life. Steam or hot oil is used as one working medium, and air is used as another working medium.

The anti-rust paint or silver powder painted on the surface of the aluminum extruded finned tube is also safe and will not emit harmful gases to the human body. Steel-aluminum finned tubes have a wide range of applications and are used in industry, agriculture, chemical industry and other fields.

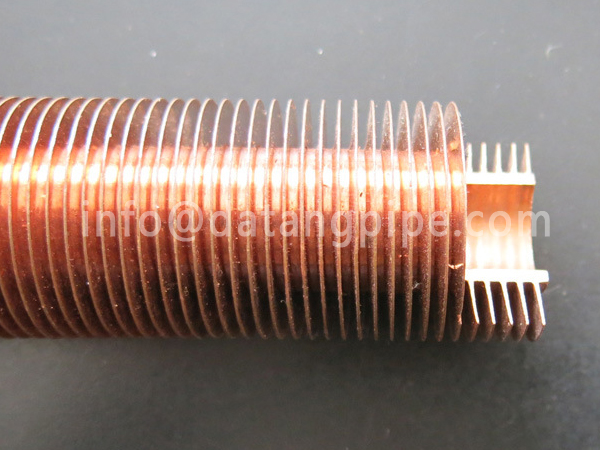

Copper-aluminum composite finned tubes are copper and aluminum tubes that are laminated and then rolled out of fins. They have the advantages of tight combination, small thermal resistance, good heat transfer performance, high strength, small flow loss, and strong corrosion resistance. It is not easy to deform under working conditions and has a long working life.

Copper extruded finned tube

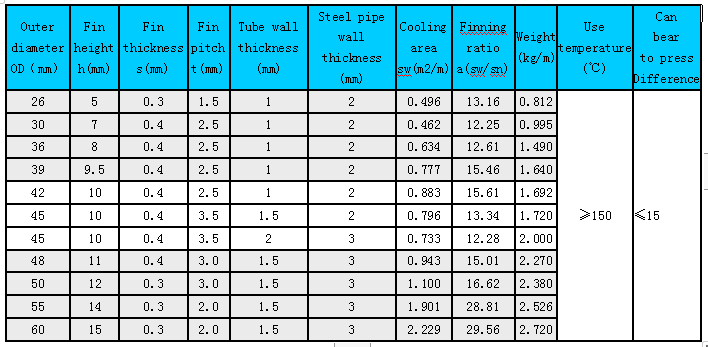

Copper-aluminum composite finned tube specification performance table

Copper extruded finned tube

The overall rolled fins are smooth and free of burrs, no wrinkles, easy to clean, easy to remove condensed water on the outer surface of the fins during wet cooling in heating and air conditioning projects, and not easy to dust and scale in drying heating and other heat exchange occasions.

The aluminum-rolled finned tubes and copper-aluminum composite finned tubes produced by our factory are all anodized on the surface, and the color is beautiful and generous, which can effectively prevent surface corrosion.