What is internally grooved low fin tube?

Internally grooved low fin tubes are generally machined to form fins of a certain height, a certain fin pitch, and a certain thickness on the outer surface of a light tube. Finned tubes are mostly used as heat exchange elements for condensers and evaporators of air conditioners, and low-fin tubes are often used in condensers.

The following is a detailed analysis of inner groove low fin tubes:

1. Definition and use of inner groove low fin tubes

Definition of low-fin tubes:

Low-fin tubes expand the heat transfer area by machining spiral fins (fins) of a certain height, fin pitch, and thickness on the outer surface of the light tube. This structure makes heat transfer more efficient and is often used in air-conditioning condensers, evaporators and other equipment.

Application: Mainly used in air-conditioning systems, refrigeration equipment, thermal power stations, nuclear power stations, and petrochemicals as core heat exchange elements for condensers and evaporators.

2. Low fin tube structure parameters

The key parameters of low fin tubes include:

Fin height: usually between 2mm and 10mm, affecting the expansion of the heat transfer area.

Fin spacing: the distance between adjacent fins is generally between 1mm and 5mm, and needs to be optimized according to the fluid characteristics.

Fin thickness: generally between 0.1mm and 0.4mm, too thick may lead to a decrease in heat transfer efficiency.

Fin shape: commonly straight or wavy (such as W-type), the wavy shape can further enhance turbulent disturbance and improve heat transfer effect.

The structural parameters of low fin tubes are mainly the inner diameter and outer diameter of the fin tube, the wall thickness of the fin tube, the fin pitch, the fin thickness and the fin height.

It is generally used in situations where the heat transfer coefficient inside the tube is more than 1 times greater than the heat transfer coefficient outside the tube. The most typical application is the oil heat exchanger. For condensation and boiling outside the tube, due to the surface tension, there is also a good effect of enhancing heat transfer. Its processing has been industrialized, and the design correlation has been verified in Changling Refinery and other plants.

(1) In terms of heat transfer effect, the primary and secondary relationship of the structural parameters of the low-finned tube is: fin pitch → fin height → fin thickness. When the fin pitch is within 1~2 mm, the heat transfer performance of the finned tube increases with the increase of the fin pitch. When the fin pitch exceeds 2mm, the heat transfer performance decreases with the increase of the fin pitch; the heat transfer performance decreases with the increase of the fin thickness and increases with the increase of the fin height.

(2) The pressure drop outside the finned tube is significantly affected by the fin height. The pressure drop increases geometrically with the increase of the fin height. The effect of the fin pitch on the pressure drop is also obvious. The pressure drop increases with the increase of the fin pitch and is almost unaffected by the fin thickness.

(3) When the fluid flow rate inside and outside the tube increases, the heat transfer and pressure drop of the finned tube also increase accordingly. When the fluid flow rate outside the tube increases, the pressure drop increase is significantly greater than the heat transfer increase, while when the flow rate inside the tube increases, the pressure drop outside the tube remains unchanged, and the pressure drop inside the tube increases slightly.

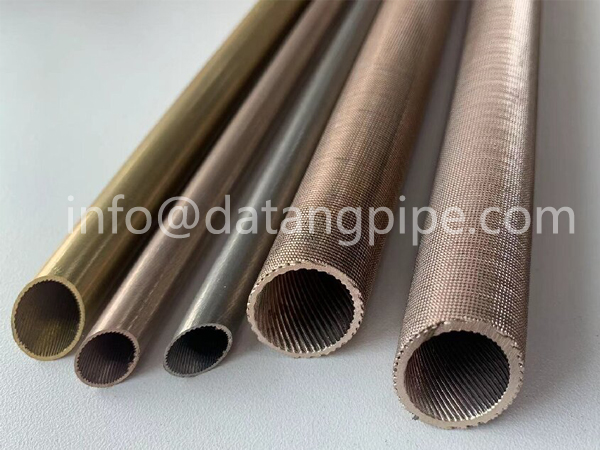

copper low fin tube

3. Production method of internally grooved copper low fin tubes

Low-finned tubes are mainly manufactured by rolling method (three-roller oblique rolling):

After the core rod is lined inside the bare tube, the tube material is driven by the roller blade to make a spiral motion to form a regular fin structure on the surface. This method ensures that the base tube and the fin are tightly combined, without contact thermal resistance or electrical corrosion problems, and has strong anti-deformation ability.

4. Performance parameters and optimization direction of internally grooved copper low fin tubes

Fin ratio (β): defined as the ratio of the total surface area of the finned tube to the surface area of the original bare tube. The higher the β value, the more significant the expansion of the heat transfer area, but it is necessary to balance material consumption and efficiency improvement.

Fin efficiency (η): The ratio of actual heat transfer to theoretical maximum heat transfer. The η value is affected by factors such as fin height and shape. Too high or too low η will lead to decreased efficiency.

Optimization direction: By adjusting the fin height, spacing and shape, combined with fluid dynamics simulation (such as CFD analysis), the heat transfer performance can be further enhanced and the resistance loss can be reduced.

5. Low fin tubes for heat exchangers material selection and application scenarios

Common materials include aluminum alloy, copper, stainless steel, etc. Among them, copper (T2/TP2) has become the mainstream choice due to its good thermal conductivity and moderate cost. The product specifications cover the outer diameter of the light end from 8mm to 50mm, which is suitable for heat exchange systems of different sizes.

Low finned tubes Use:

Low finned tubes are widely used in condensers, evaporators and other equipment of air conditioners due to their excellent heat transfer performance, and are an important part of these equipment.

Advantages of integral low fin tubes

High heat exchange efficiency: Due to the presence of fins, low-fin tubes have a larger surface area and can achieve higher heat exchange efficiency with the same metal material consumption.

Strong anti-deformation ability: The low-fin tubes produced by the rolling method have a base tube and an outer fin tightly combined as a whole, so that the fin tubes have good anti-deformation ability during use.

No contact thermal resistance and electrical corrosion problems: Since there is no need for welding or other connection methods between the base tube and the outer fin, there is no problem of contact thermal resistance and electrical corrosion.

Low-fin tubes are a type of heat exchange element with excellent heat exchange performance, strong anti-deformation ability and long service life. They play an important role in condensers, evaporators and other equipment of air conditioners.

Datang fin tube product’s specification outside diameter from 18 mm to 273 mm finned tube, The process includes high-frequency welded fin tubes, extruded fin tubes, L / L L / K L fin tubes, G -type Embedded fin tubes, low fin tubes, inner fin tubes, elliptical fin tubes, longitudinal fin tube,H type fin tube, the annual capacity can reach 100,000 tons.

We have professional engineer support, high efficiency sales team and competitive price superiority.

Our R & D department provides the strong technical support and enables us to receive some, O D M projects, and can provide you with drawings, design plans and thermal calculations, service has exceeded more than 3000 enterprises.

If you need finned tubes, contact us! Email:info@datangpipe.com,Whatsapp:+86 15690122018