What is laser welded fin tube?

Laser welded fin tube is a heat exchange element that firmly connects the fins to the base tube through laser welding technology. This structure not only increases the heat exchange area, but also improves the heat exchange efficiency, making the laser welded fin tube show excellent performance and application value in the field of industrial heat exchange.

What is laser welded fin tube

Laser welded fin tube is a heat exchange tube that firmly connects the fins to the base tube through laser welding technology. The fins and base tubes can be made of a variety of materials such as stainless steel, titanium, copper, carbon steel, etc. to meet the needs of different application scenarios. This structure not only increases the heat exchange area, but also improves the heat exchange efficiency, making laser welded fin tubes the preferred heat exchange element in many industrial fields.

Working principle of laser welded helical fin tube

Laser welded fin tubes are mainly composed of base tubes and fins. The base tube is usually made of high-quality materials such as stainless steel (such as 304, 316L, etc.), carbon steel, etc., and the fins are firmly attached to the surface of the base tube through laser welding technology.

Laser welding technology uses a high-energy-density laser beam to melt the contact area between the fin and the base tube instantly, forming a strong metallurgical bond, thereby realizing the welding of the fin and the base tube. This structural design greatly improves the heat transfer efficiency, can withstand greater working pressure, and is suitable for various harsh working conditions.

Laser welded spiral fin tube manufacturing process

The manufacturing process of laser welded fin tube mainly includes raw material preparation, cutting and blanking, forming processing, cleaning processing, pretreatment, equipment debugging, clamping and positioning, welding operation, appearance inspection, dimension measurement, weld detection, performance testing, cleaning processing and anti-corrosion treatment.

In the raw material preparation stage, it is necessary to select suitable base tube and fin materials.

The base tube is usually made of high-quality materials such as stainless steel (such as 304, 316L, etc.) and carbon steel, and requires a smooth surface without obvious defects. The fin material is selected based on factors such as thermal conductivity, corrosion resistance and cost.

In the cutting and blanking stage, the fin material is cut into the required shape and size using equipment such as a laser cutting machine or a plasma cutting machine. In the forming stage, the cut fins are bent, rolled and other forming processes are performed to make them fit better with the base tube.

In the cleaning and pretreatment stage, the welding surfaces of the base tube and the fin are cleaned to remove impurities such as oil, rust, and dust to improve the welding quality. If necessary, the base tube and the fin surface can also be pre-treated by nickel plating, copper plating, etc. to improve welding performance and corrosion resistance.

In the equipment debugging stage, according to the material, thickness and other parameters of the base tube and the fin, the power, frequency, pulse width, welding speed and focus position of the laser welding machine are accurately adjusted. In the clamping and positioning stage, the base tube and the fin are clamped and positioned according to the design requirements to ensure that the relative position between the two is accurate.

In the welding operation stage, the laser welding machine is started to focus the laser beam on the joint between the base tube and the fin, so that the local metal is quickly melted to form a molten pool. As the laser beam moves, the molten pool cools and solidifies, thereby achieving a firm connection between the base tube and the fin. At the same time, protective gas (such as argon, helium, etc.) is introduced to prevent oxidation and nitridation of the weld.

After welding, appearance inspection, dimension measurement, weld inspection and performance testing are required to ensure that the quality of the laser welded fin tube meets the design requirements. Finally, cleaning and anti-corrosion treatment are carried out to improve the corrosion resistance and service life of the laser welded fin tube.

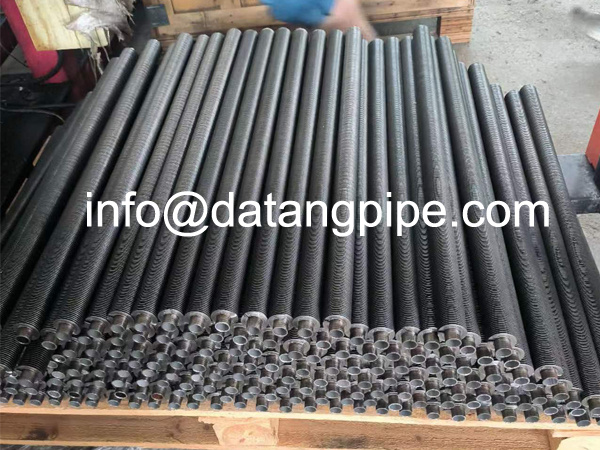

304 316L stainless steel spiral 32mm laser welded fin tube

Application fields and advantages of laser welded fin tubes

Laser welded fin tubes have been widely used in many industries, including chemical industry, electric power, refrigeration, oil and gas mining, thermal power generation, nuclear power generation, oil and gas pipeline transportation, centralized heating system, etc.

Application fields of laser welded fin tubes

Laser welded fin tubes have been widely used in many industrial fields due to their high efficiency in heat exchange performance, corrosion resistance and strong durability.

In the power industry, laser welded fin tubes are used in the air preheater of boilers, which can effectively improve the heat exchange efficiency, reduce the exhaust temperature and improve the energy utilization rate. Its precise welding process ensures the close integration of the fins and the base tube, and can withstand high temperature, high pressure and complex thermal stress environment, ensuring the long-term stable operation of the equipment.

In the petrochemical industry, petrochemical production involves a variety of corrosive media and high temperature and high pressure working conditions. Laser welded fin tubes can be used in various types of heat exchangers, condensers and evaporators due to their high welding quality and high weld strength. For example, in crude oil distillation units, laser welded fin tubes can efficiently achieve heat exchange while resisting the corrosion of crude oil and related products to maintain the normal production of the device.

In the refrigeration and air-conditioning industry, laser welded fin tubes are key components of condensers and evaporators. Due to their good heat exchange performance, they can quickly realize the heat transfer of refrigerants and improve refrigeration efficiency. Its high-precision welding ensures the sealing of the product, prevents refrigerant leakage, and helps maintain the stable operation of the refrigeration system. Therefore, laser welded fin tubes are widely used in large central air conditioners and cold storage refrigeration equipment.

In the field of new energy, laser welded fin tubes also play an important role. In the solar thermal utilization system, laser welded fin tubes are used in collectors, which can efficiently absorb solar energy and convert it into heat energy. In the thermal management system of new energy vehicles, it can achieve effective heat dissipation of battery packs and motors, ensure that key components of new energy vehicles work at a suitable temperature, and improve the performance and safety of the vehicle.

In addition, with the continuous increase in the power of electronic equipment, the demand for heat dissipation is becoming increasingly prominent. Laser welded fin tubes are used in heat dissipation modules of servers, high-power electronic devices, etc. due to their lightness and efficient heat exchange. The compact structure achieved by precise welding can provide strong heat dissipation capacity in a limited space to ensure the stable operation of electronic equipment.

Stainless steel Finned Tube for heat exchanger

The significant advantages of laser welded fin tubes include:

Energy saving and high efficiency:

High-quality welds reduce heat loss and fluid resistance, increase heat exchange area, and improve heat exchange efficiency by 20%-30% compared with traditional fin tubes.

Low cost:

The thickness of the base tube and fin is small, saving material costs.

High penetration rate:

It can achieve a firm connection between the fin and the base tube, prevent gap corrosion, and extend service life.

Easy to process:

It can directly carry out secondary processing such as coils and bends, and adapt to various complex engineering application scenarios.

Small hot zone impact:

The metallographic changes are small, which reduces the impact on material properties during welding.

Advantages and characteristics of laser welded fin tubes

The reason why laser welded fin tubes can be widely used in many industrial fields is mainly due to its following advantages and characteristics:

1. Efficient heat exchange:

Laser welding technology forms a close connection between the fins and the base tube, increases the heat exchange area, and improves the heat exchange efficiency.

2. Strong corrosion resistance:

Laser welded fin tubes can be made of corrosion-resistant materials such as stainless steel and titanium, and are suitable for a variety of corrosive media environments.

3. Strong durability:

Laser welding technology has the advantages of high weld strength and small welding deformation, which enables laser welded fin tubes to withstand greater working pressure and harsh working conditions.

4. Easy to process:

Laser welding technology breaks through material limitations and can be customized using different materials to meet the needs of different application scenarios.

5. Energy saving and environmental protection:

The high efficiency heat exchange performance of laser welded finned tubes helps to reduce energy consumption and improve energy utilization, which is in line with the development trend of energy saving and environmental protection.

As a high-efficiency heat exchange element, laser welded finned tubes have demonstrated excellent performance and application value in many industrial fields. With the continuous development of science and technology, the technical level of laser welded finned tubes will be further improved, bringing more innovations and breakthroughs to the field of industrial heat exchange.

Datang fin tube product’s specification outside diameter from 18 mm to 273 mm finned tube, The process includes high-frequency welded fin tubes, extruded fin tubes, L / L L / K L fin tubes, G -type Embedded fin tubes, low fin tubes, inner fin tubes, elliptical fin tubes, longitudinal fin tube,H type fin tube, the annual capacity can reach 100,000 tons.

We have professional engineer support, high efficiency sales team and competitive price superiority.

Our R & D department provides the strong technical support and enables us to receive some, O D M projects, and can provide you with drawings, design plans and thermal calculations, service has exceeded more than 3000 enterprises.

If you need finned tubes, contact us! Email:info@datangpipe.com,Whatsapp:+86 15690122018