What you should know about high-frequency welded spiral serrated fin tubes

What you should know about high-frequency welded spiral serrated fin tubes

High-frequency welded spiral serrated fin tubes are efficient heat transfer elements. Their special structure and high-frequency welding technology achieve efficient heat transfer and are widely used in petrochemical, electric power and other fields. They are compact, wear-resistant and corrosion-resistant, and reduce energy consumption, but attention should be paid to the effects of water quality and welding quality on performance.

High-frequency welded spiral serrated fin tubes are efficient heat transfer elements that play an indispensable role in various industrial fields. Through special structural design and high-frequency welding technology, they achieve efficient heat transfer and provide strong support for modern industrial production.

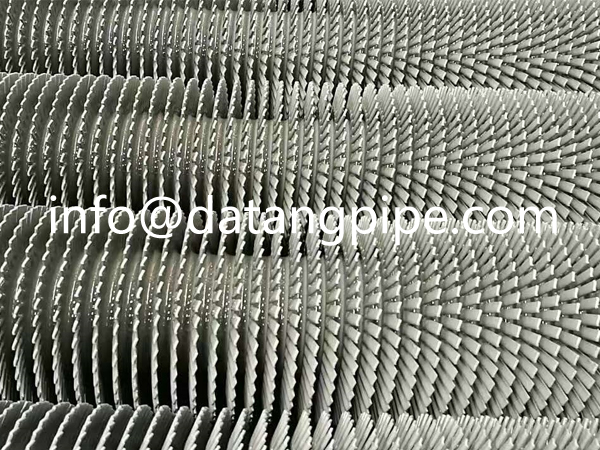

The structural design of high-frequency welded spiral serrated fin tubes is the basis of their efficient heat transfer. It usually consists of a base tube and a toothed fin, which is spirally wound on the outer surface of the base tube. The toothed design increases the contact area between the fin and the fluid, allowing heat to be transferred from the fin to the fluid more quickly.

The spiral shape causes the fin to form a continuous disturbance in the fluid, enhancing the convective heat transfer effect of the fluid. This structural design enables the open-tooth high-frequency welded spiral fin tube to achieve higher heat transfer efficiency under the same conditions.

High-frequency welding technology is the key to the manufacturing process of open-tooth high-frequency welded spiral fin tubes. High-frequency welding uses the skin effect and proximity effect generated by high-frequency current to quickly heat the metal in the welding area to a molten state, thereby achieving a firm connection between the fin and the base tube. This welding method is not only fast and efficient, but also has high weld quality and strength.

The application of high-frequency welding technology enables high-frequency welded spiral serrated fin tubes to maintain high precision and stability during the manufacturing process, thereby ensuring its excellent heat transfer performance during use.

High-frequency welded spiral serrated fin tubes have a wide range of applications, involving multiple industrial fields. In the field of petrochemicals, it is widely used in various heaters and coolers, which can effectively transfer heat to materials or cooling media and improve production efficiency.

In the field of electricity, high-frequency welded spiral serrated fin tubes are used in heat exchangers in generator sets, which can quickly transfer the heat generated by the generator set to the cooling medium to ensure the normal operation of the generator set.

In the fields of metallurgy, pharmaceuticals, food, etc., high-frequency welded spiral serrated fin tubes also play an important role, providing an effective solution for heat transfer of various equipment.

In addition to efficient heat transfer performance, high-frequency welded spiral serrated fin tubes also have some other advantages. First, its compact structure and small size make it easy to install and maintain. This makes it widely used in occasions with limited space.

High-frequency welded spiral serrated fin tubes have good wear resistance and corrosion resistance, and can be used for a long time in harsh working environments.

Due to its efficient heat transfer performance, high-frequency welded spiral serrated fin tubes can reduce energy consumption during operation and achieve the goal of energy conservation and emission reduction.

However, high-frequency welded spiral serrated fin tubes also need to pay attention to some problems during use. First of all, water quality has a great influence on the performance of fin tubes. If the water quality is poor, it is easy to cause scaling, corrosion and other problems, thereby affecting the heat transfer effect and service life of the fin tubes.

During use, the fin tubes need to be cleaned and maintained regularly to ensure that they are in good working condition.

Welding quality is also a key factor affecting the performance of fin tubes. If quality problems occur during the welding process, such as loose welds and welding deformation, the heat transfer performance and service life of the finned tube will be adversely affected.

The welding quality needs to be strictly controlled during the manufacturing process to ensure the stable and reliable performance of the finned tube.

High-frequency welded spiral serrated finned tube is an efficient, compact and durable heat transfer element with broad application prospects in various industrial fields.

With the continuous advancement of science and technology and the continuous improvement of technology, it is believed that high-frequency welded spiral serrated finned tubes will play a more important role in the future and provide more efficient and environmentally friendly heat transfer solutions for modern industrial production.