Technical characteristics of studded tube and pipe

Technical Characteristics of Studded Tubes

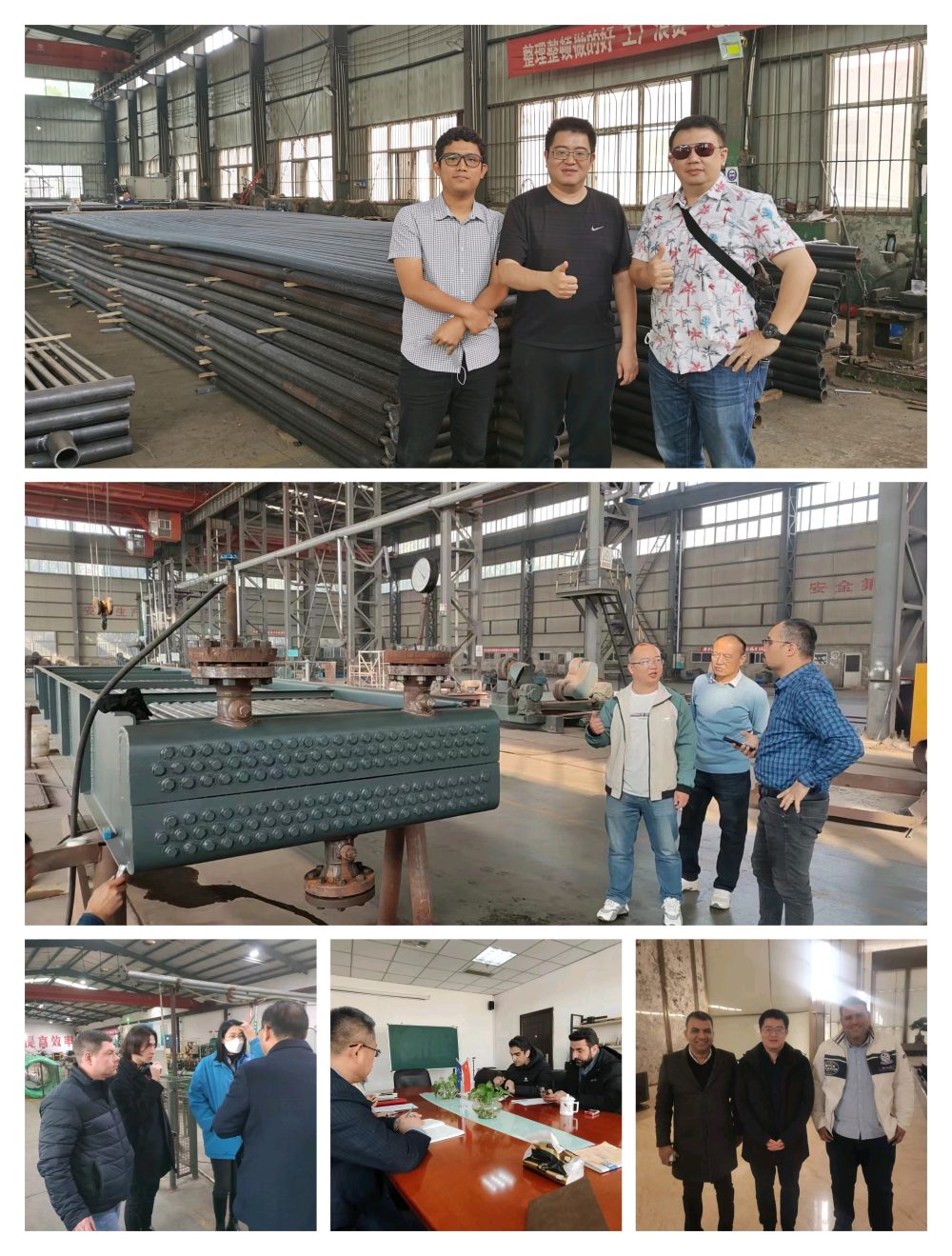

Stud Fin Tubes (also known as Studded Tube) using a quadrilateral or hexagonal arrangement, equal parts welded to the surface of the heat exchanger tube cylindrical needle.

Strengthened by the quadrilateral or hexagonal heat exchanger nail header tube assembly welding constitutes a high-efficiency energy-saving needle tube heat exchanger tube group, because the nail header tube needle ribs is a cantilevered structure, compact structure, the impact of the gas flow under the action of the needle ribs to produce oscillation, so that it is difficult to build up the soot; coupled with the intense turbulence of the flue gas scouring, so that the nail header tube heat transfer element heat transfer efficiency is high, and has a strong capacity of the self-cleaning ash. In the petrochemical industry, the Stud Fin Tubes has a wide range of applications.

Especially in the convection chamber of the tube heating furnace, in order to strengthen the heat transfer effect outside the tube, the heat transfer element is often used Stud Fin Tubes. Stud Fin Tubes can improve the heat transfer coefficient of the flue gas side, Stud Fin Tubes area for the light tube 2 to 3 times, due to the application of Stud Fin Tubes so in the case of reasonable design can be obtained with the radiation of the same heat intensity.

Stud Fin Tubes equipment adopts resistance welding welding method, the welding process is controlled by PLC program, the feeding motor and indexing adopts servo motor, the man-machine interface can set the number of nail head, indexing parameters and compensation coefficients, which can be set according to the process requirements to ensure product quality and accuracy.

Stud Fin Tubes, also known as “nail head welded pipe” or “spiral submerged arc welded pipe”, is a special type of steel pipe, which is widely used in oil, gas, water and other fluid transportation systems.

Studded Tube technical characteristics are mainly reflected in the following aspects:

1. High strength and durability: Nailhead pipe undergoes rigorous welding process to ensure that the pipe body is firmly connected, able to withstand high pressure and harsh environments, and suitable for a variety of complex geological and climatic conditions.

2. Excellent sealing: Its unique welding method makes the pipe joints closer, reducing the possibility of leakage and ensuring the safety and stability of fluid transmission.

3. Efficient construction: Nailhead pipe adopts spiral welding process, high production efficiency, fast construction progress, which can greatly shorten the construction period and reduce project costs.

4. Good adaptability: Due to its special structural design and excellent mechanical properties, Nailhead Pipe is able to adapt to a variety of terrain and geological conditions, especially in complex terrain and geological conditions with excellent performance.

5. Environmental protection and energy saving: in the process of production and use, Nailhead Pipe meets the requirements of environmental protection, can reduce energy consumption and environmental pollution, in line with the concept of sustainable development.

In summary, with its high strength, durability, excellent sealing, efficient construction, good adaptability and environmental protection and energy saving, Nailhead Pipe has a wide range of application prospects in the field of fluid transportation.