Project Description

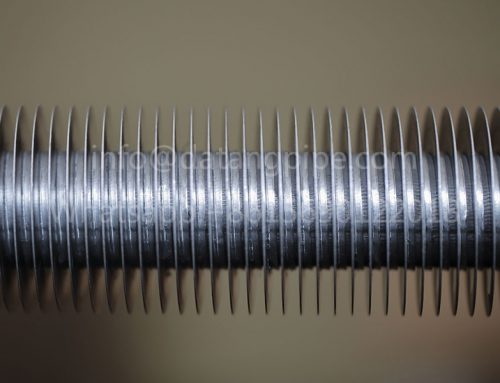

- Product Name: Finned Tube ‘L’ (Wrap On /L Foot) Fin | L Foot fin tube | Wrap On finned tube

- Leave Your Message

L Foot finned tube, also known as Wrap On finned tube and L type finned tube, is a highly efficient heat exchange element consisting of a base tube and L-shaped fins, which are fixed to the base tube by high-frequency welding or mechanical winding, thereby increasing the heat exchange area and optimizing the heat transfer efficiency.

Structural features of L Foot finned tube

The design features of L-type finned tube include:

Increase heat exchange area: The L-type fin design can significantly increase the heat exchange area on the air side, thereby improving the overall heat exchange efficiency.

Promote fluid turbulence: The L-type fin promotes fluid turbulence, further improves heat exchange efficiency, and reduces energy consumption.

Seamless connection: High-frequency welding technology ensures seamless connection between fins and base tubes, prevents thermal resistance, and enables heat to be transferred quickly and evenly.

L Foot fin tube application areas

L-type fin tubes are widely used in many industrial fields, including:

Petroleum, chemical, electric power, metallurgy: used for waste heat recovery, boiler energy-saving transformation and air preheating systems.

Green energy: in solar thermal collection systems, geothermal energy utilization and industrial waste heat power generation projects, as core heat exchange elements, efficiently collect and convert heat energy.

Food industry: used for air heaters in spray drying systems for plant protein powder, starch, etc..

L Foot Fin Tube Product Benefits

• Economic solution.

• Relative thin wall core tubes can be used.

• Some atmospheric corrosion protection of the core tube.

• Enhanced heat transfer with the L foot.

Fin Contact: Interference fit.

Maximum Tube Wall Operating Temperature:

130°C.

Type of Service: Low temperature.

L Foot Fin Tube Manufacture

Fin strip is pre-formed into an accurately controlled L shape, rolled in a uniform taper, and helically wound under tension onto a tube.

The foot of one fin butts up against the next fin and there is no gap between the fins giving a degree of coverage to the core tube.

| Parameter | Specification |

|---|---|

| Fin Material | Aluminum / Copper25 |

| Core Tube Material | Carbon Steel / Carbon Alloy Steel / Stainless Steel / Nickel Alloys / Copper / Copper Alloys / Titanium1 |

| Tube Diameter | 1/2″ (12.7mm) to 2″ (50.8mm)16 |

| Tube Wall Thickness | > 0.035″ (0.889mm) depending on tube material and outside diameter14 |

| Tube Overall Length | 300mm to 20000mm46 |

| Fin Heights | 3/8″ (9.525mm) to 1″ (25.4mm)5 |

| Fin Pitches | 5 to 12 fins per inch5 |

| Fin Strip Thickness | 0.012″ (0.30mm) to 0.020″ (0.50mm)5 |

The table summarizes the specifications for finned tube components, including material options and dimensional ranges. Copper alloys mentioned include UNS C70600 and C71500 series1, while aluminum specifications reference extruded profiles in 6063-T4 alloy5. The dimensional tolerances account for both imperial and metric measurements14.

Other fin configurations are possible.