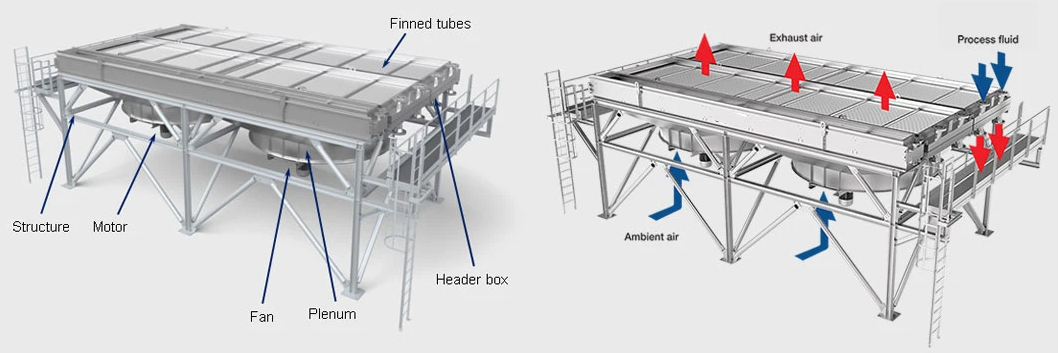

Horizontal Industrial Air Cooled Heat Exchanger with Finned Tubes

- Leave Your Message

General Description

Air cooled heat exchanger(ACHE) with fin tube can directly cool the medium by air without water. Its biggest advantages are Water and Energy Saving effectively during their service life.

The air cooled heat exchangers are mainly used for the condensation and cooling of vaporous, gaseous and liquid substances. It can be used in the refining, petrochemical and related technological processes, like cooling high-viscosity liquid products, natural gas, water, etc.

Datang Fin Tube can manufacture both forced draft and induced draft ACHE according to requirements.

To meet specific application demands, Datang Fin Tube also can offer V frame air cooled heat exchanger.

Working Principle

Finned tube bundle, screw tube header, louver and fan are main parts.

TECHNICAL SPECIFICATIONS

| Part Models | Tubes QTY | Pressure (MPa) |

Tube bank QTY |

Bare tube heat transfer area(m2) | Finned tube heat transfer area(m2) |

| GP12x3-4-172-1.6S-23.4/L(DR)-Ia | 182 | 1.6 | 4 | 172 | 4025 |

| GP12x3-4-172-2.5S-23.4/L(DR)-Ia | 2.5 | ||||

| GP12x3-4-172-4.0S-23.4/L(DR)-Ia | 4.0 | ||||

| GP12x3-8-344-4.0S-23.4/L(DR)-Ia | 364 | 4.0 | 8 | 344 | 8050 |

| GP9x2-6-126-1.6S-23.4/L(DR)-Ia | 177 | 1.6 | 6 | 126 | 2948 |

| GP6x1-8-52.2-4.0S-23.4/L(DR)-Ia | 108 | 4.0 | 8 | 52.2 | 1221 |

Above models are just for your reference, and you can contact us for more details.

Horizontal Industrial Air Cooled Heat Exchanger with Finned Tubes

APPLICATIONS

Dry cooler can be widely used in different industrial fields for heat transfer processes, such as: chemical, oil & gas, power generation…

It is widely used in the desert oil industry air cooling system.

FAQ

1, Delivery Time

15-40days (depending on stock)

2, Required Parameters

Use Purpose, Fluid material and percentage(if mixture), Fluid flow rate, Fluid temperature(inlet & outlet), Fluid pressure(inlet), Ambient dry-bulb temperature, Installation area(if required)

Industry Cooler Finned Tube Dry Cooled Air Cooled Heat Exchanger

Horizontal Industrial Air Cooled Heat Exchanger with Finned Tubes referred to as air cooler, air as a coolant, can be used as a cooler, can also be used as a condenser.

The air cooler is mainly composed of tube bundle, support and fan. Air cooler The hot fluid flows in the tube and the air blows through the tube bundle. Because the amount of ventilation required for heat transfer is large, and the wind pressure is not high, axial flow fans are often used (see fluid conveying machinery). The type and material of tube bundle have great influence on the performance of air cooler. Because the heat transfer coefficient of the air side is very small, the tube is often added with fins to increase the heat transfer area and fluid turbulence, and reduce the thermal resistance. Most air coolers use radial fins.

The air cooler usually uses a light tube with an outer diameter of 25mm, a low fin tube with a fin height of 12.5mm and a high fin tube with a fin height of 16mm. The fins are generally made of a material with a high thermal conductivity (most commonly aluminum) and are wound or set onto the light tube. In order to strengthen the heat transfer effect of the air cooler, it can be humidified by spraying water in the inlet air. This not only reduces the air temperature, but also increases the heat transfer coefficient.

The use of air coolers can save a lot of industrial water, reduce environmental pollution, and reduce infrastructure costs. Especially in water-scarce areas, air cooling instead of water cooling can alleviate the contradiction of water shortage.