Project Description

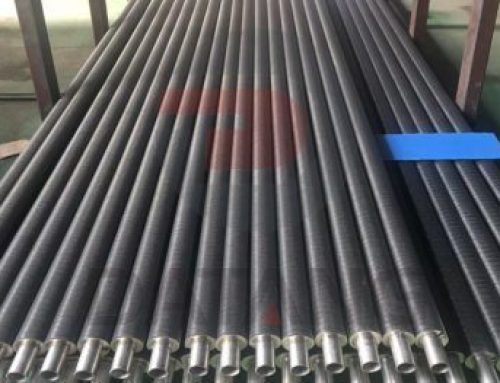

Product Name: Copper Laser-Welded Spiral Fin Tubes for Heat Exchangers

- Leave Your Message

Copper Laser-welded finned tubes for heat exchangers

Laser-welded spiral finned tubes are used in residential wall-mounted boilers, industrial boilers, and other applications. Their advantage lies in zero contact thermal resistance. Compared to high-frequency welded finned tubes, they offer a higher fin-to-fin ratio, lighter weight, and a more compact assembled heat exchanger. They are more energy-efficient and environmentally friendly, meeting national emission standards.

Laser-welded finned tubes are available in stainless steel, titanium, copper, carbon steel, and other materials.

Laser-welded finned tubes are technologically advanced products with irreplaceable advantages.

1: Base tube thickness can range from 0.8 to 3 mm, and fin thickness can range from 0.3 to 0.8 mm, significantly reducing material costs compared to other processes.

2: High weld penetration prevents crevice corrosion, extends service life, and reduces heat transfer resistance.

3: Breaking through material limitations, allowing processing with diverse materials.

4: Easily accessible for secondary processing, allowing for direct coiling and bending.

5: A small heat-affected zone and minimal metallographic changes make processing of small-diameter finned tubes possible.

Laser-welded finned tubes, as highly efficient heat transfer components, demonstrate significant advantages in modern industry. Their core principle is to securely bond the fins to the base tube through laser welding, forming an integrated structure. This process overcomes the technical limitations of traditional wound-fin and sleeve-fin tubes, achieving a qualitative leap in heat exchange efficiency, structural strength, and service life.

From the power and petrochemical industries to new energy sectors, laser-welded finned tubes are gradually replacing traditional heat exchange components and becoming a key technology for improving the performance of industrial equipment.

1. Laser-welded finned tubes are a revolutionary breakthrough in heat transfer efficiency

The most prominent advantage of laser-welded finned tubes lies in their exceptional heat transfer performance. The metallurgical bonding achieved through a high-energy-density laser beam creates an ultra-thin weld layer, less than 0.1 mm, between the fins and the base tube, reducing thermal resistance by over 60% compared to traditional mechanical joining methods.

Measured data shows that under the same operating conditions, the heat transfer coefficient of laser-welded finned tubes can reach 1.8-2.3 times that of wound-fin tubes. This characteristic is particularly evident in waste heat recovery systems. After a petrochemical company retrofitted its catalytic cracking unit with laser-welded finned tubes, the flue gas waste heat recovery rate increased from 62% to 89%, saving 12,000 tons of standard coal annually.

The unique continuous welding structure eliminates the contact thermal resistance problem associated with traditional finned tubes. Mechanically joined fins are prone to micro-gaps under high-temperature and high-pressure environments, while the metallurgical bond formed by laser welding maintains long-term stable thermal conductivity.

A nuclear power plant steam generator retrofit project demonstrated that the use of laser-welded finned tubes increased the overall heat transfer efficiency of the tube bundle by 35%, and after five years of operation, the performance degradation was less than 3%, far exceeding international nuclear power standards.

II. A Dramatic Improvement in the Structural Strength of Laser-Welded Finned Tubes

Laser welding technology imparts remarkable mechanical properties to finned tubes. The tensile strength of the welded joint can reach over 95% of that of the base material, and the vibration fatigue life is 10 times longer than that of mechanically joined finned tubes.

Oil coolers constructed with laser-welded finned tubes successfully passed a 200-hour continuous vibration test (15G acceleration) with zero fin shedding, fully meeting the extreme operating conditions of fighter aircraft.

This structural advantage also offers outstanding corrosion resistance. The dense welds formed by laser welding effectively block media penetration. A heat exchanger application on an offshore platform demonstrated that, in a marine environment with Cl- concentrations exceeding 5000 mg/L, laser-welded finned tubes maintained service for eight years without crevice corrosion, while conventional sleeve tubes required replacement after an average of three years. Precise heat input control during the welding process (typically less than 0.5 kJ/cm2) also minimizes intergranular corrosion, making the product suitable for use in highly corrosive environments.

III. Geometrically Increased Service Life of Laser-Welded Finned Tubes

The metallurgically bonded interface properties give laser-welded finned tubes remarkable durability. Actual operating data demonstrates a service life of 15-20 years at an operating temperature of 400°C, more than three times that of conventional finned tubes.

Comparative testing at a cogeneration project revealed that conventional high-frequency welded finned tubes experienced extensive fin loosening after four years of operation, while laser-welded finned tubes installed at the same time maintained over 97% of their initial heat transfer capacity after 12 years of operation.

This longevity is due to a triple guarantee: metallurgical stability of the weld interface, fatigue resistance from residual compressive stress, and a surface-strengthening layer formed by laser finishing. In waste incineration power generation, laser-welded finned tubes exhibit excellent wear resistance in the face of constant erosion from dust-laden flue gases. Operational data from one project showed an annual wear rate of only 0.03mm, far below the industry’s recommended threshold of 0.15mm.

Fourth, Laser-welded Finned Tubes Are a Pioneer in Energy Saving and Consumption Reduction

The compact design of laser-welded finned tubes offers significant energy savings. Their fin-to-fin ratio (fin surface area/base tube surface area) can reach 20:1, reducing equipment size by over 40%.

In a heat exchange network renovation case study at a large chemical company, the use of laser-welded finned tubes reduced the weight of a single heat exchanger by 18 tons, lowered the power of the associated fan by 132 kW, and saved over 1 million kWh of electricity annually.

Environmental advantages are also evident in the manufacturing process. The digital processing capabilities of laser welding increase material utilization to 98%, reducing waste generation by 60% compared to traditional processes.

According to practical data from one manufacturer, annual production of 100,000 finned tubes saves 150 tons of stainless steel sheet, equivalent to a reduction of 420 tons of carbon emissions. The welding process eliminates the need for flux and shielding gas, completely eliminating heavy metal pollution and greenhouse gas emissions.

V. The Outstanding Performance of Laser-Welded Finned Tubes in Various Applications

In the new energy sector, laser-welded finned tubes are driving technological innovation. A solar thermal power plant using specially coated laser-welded finned tubes has increased the number of starts and stops for a molten salt heat exchanger from 300 to over 1,000. In the hydrogen fuel cell sector, its microchannel design reduces the cooling plate volume by 60%, helping the battery stack power density exceed 5kW/L.

The performance under special operating conditions is even more impressive. Testing in a cryogenic environment (-196°C) shows that the impact toughness of laser-welded finned tube welds remains at 85% of that at room temperature, enabling safe, zero-leakage operation in a liquid hydrogen storage tank application. In a supercritical CO2 power generation system, its ability to withstand 25 MPa pressure is twice that of traditional structures, enabling system thermal efficiency to exceed 52%.

VII. Lifecycle Cost Advantages of Laser-Welded Finned Tubes

Although the initial investment is 30-50% higher than traditional products, the comprehensive benefits of laser-welded finned tubes are significant. An economic analysis of a refinery shows that, considering energy savings, maintenance costs, and replacement cycles, total costs can be reduced by 42% over five years. Power industry calculations indicate that the use of laser-welded finned tube heat exchangers per MW unit can generate additional revenue of 1.2-1.8 million RMB over its lifetime.

This cost advantage is even more pronounced in high-end sectors. Laser-welded finned tube HVAC systems used in cleanrooms in the semiconductor industry, thanks to their maintenance-free nature, have reduced wafer shop downtime by 85 hours annually, equivalent to an increase in output value of 230 million yuan. In the pharmaceutical industry, their cleanliness meets GMP Class A standards, eliminating the risk of batch scrapping caused by particle shedding in traditional finned tubes.

With the advancement of the “dual carbon” strategy, laser-welded finned tube technology will continue to evolve. Innovations such as nanostructured welding and intelligent thermally responsive materials are being developed in laboratories, and in the future, super-finned tubes with heat transfer coefficients exceeding 10,000 W/(m²·K) may emerge. This innovative technology, which combines precision manufacturing with heat transfer science, is expected to provide stronger technical support for industrial energy conservation and consumption reduction, becoming a key technological path to achieving carbon neutrality.

The materials used for heat exchanger tubes and condenser tubes should possess excellent heat transfer performance, as well as excellent corrosion, erosion, and abrasion resistance. They should also have good strength, rigidity, and plasticity for ease of processing and manufacturing.

Datang Fin Tube has accumulated many years of experience in high frequency welding fin tubes, square fin tubes, mosaic fin tubes, and rolled composite steel aluminum fin tubes.