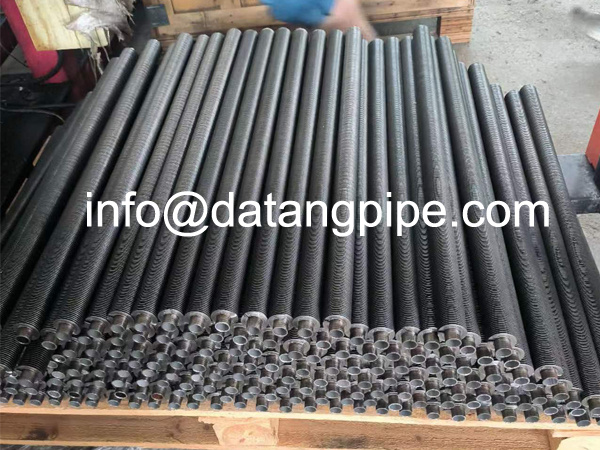

Laser Welded Fin Tube for Heat Exchanger

Product Description: 100% welded between fin and tube without filling material.The laser welding in the weld.

Pipe outer diameter 8.0-50.0 mm,Wing outer diameter 17.0-80.0 mm,wing pitch 5-13 fins / inch,wing height 5.0-17 mm,fin thickness 0.4 1.0 mm, maximum pipe length 12.0 m.

usually,Squeeze wings Utend Power plant, chemical industry, heat recovery plant, thermal industry

The maximum operating temperature is 400 C.

Laser Welded Finned Tubes

In addition to the manufacturing of high-frecuency finned tubes, Datang offers its customers the manufacturing of finned tubes by laser welding for increased efficiency and higher quality. This laser welding production line was developed by our engineers combining both our large experience manufacturing extended surface and the most modern laser technology available in the market.

Laser Welded Spiral Fin Tube by Material

Laser Welded Spiral Fin Tube by Application

In the compromise of offering to our clients the best possible product with the higher performance for its function, Datang has the possibility of manufacturing finned tubes by laser welding for increased efficiency and higher quality.

This line was developed by our engineers combining both our large experience manufacturing extended surface and the most modern laser technology available in the market.

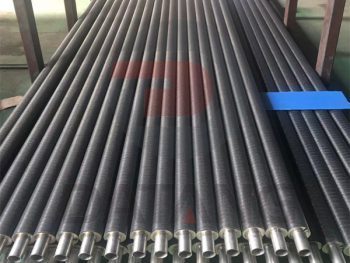

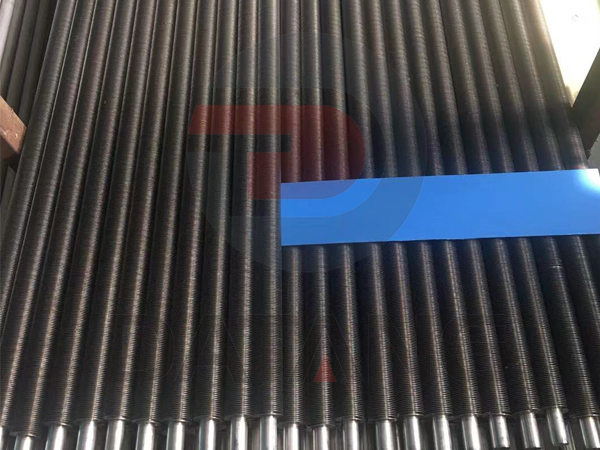

The fins (solid or serrated) are helically wound and continuously welded to the tube by a fully automatic laser finning machine. This new laser finning process produces a perfect fin-to-tube bond with lower heat input and improved efficiency in heat flow and resistance to corrosion.

Advantages of Finned Tubes Welded by Laser

Highest quality product

Wider range of products in both geometry and materials

Price saving

Highest Quality Product

The perfect bond between fin and tube improves efficiency in heat transfer and resistance to corrosion resulting in a clean weld fin to tube joint and fully straight fins (no corrugation).

New Material Combinations And Range Of Production

Our Laser Finning Process allows a wider dimensional range of tube and fin combinations. Feasible height, thickness and pitch of fins go way beyond any conventional finning process.

In addition, an increased range of material combinations of both tube and fin (steel, aluminum, copper, titanium) offers new advantages and alternatives to the industry.

Price Saving

Lower energy consumption, reduced cost of consumables and increased efficiency of the process allow us to offer very competitive prices.