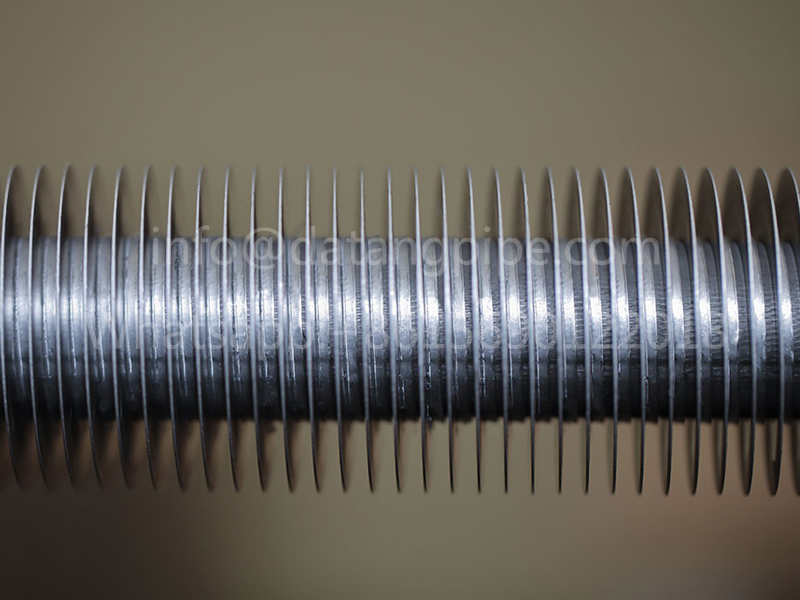

Wound L/LL/KL/KLM Knurled L Type Finned Tube for Heat Exchanger

Spiral wound fin tube(L/LL/KL type fin tube)

1. L-type spiral wound fin tube

The trapezoidal cross section formed by the rolling of the L-type fin tube is consistent with the heat flux density distribution, the tube is tightly combined, the thermal efficiency is high, and the contact thermal resistance caused by the gap between the fins is eliminated. Working temperature: 230℃. Features: The winding process is adopted, the production efficiency is high, the fin spacing is uniform, the heat transfer performance is good, the fin rate is high, and the base tube can be protected from air erosion.

Spiral wound fin tube(L/LL/KL type fin tube)

2.KL-type KLM Spiral Wound Fin Tube

KL-type(KLM) fin tube, also known as knurled fin tube, is a fin tube that is rolled on the base tube before winding the fin, or a blade is installed on the winding machine to knurl the base tube, and the back blade is wound, knurled and wound at the same time. The maximum operating temperature is <250℃ and the maximum operating pressure is <3.2MPa.

Spiral wound fin tube(L/LL/KL type fin tube)

3.LL-type Spiral Wound Fin Tube

LL-type spiral wound fin tube: On the basis of the L-type, the root of the fin is completely covered on the outer surface of the base tube, which enhances the contact surface and improves the heat transfer effect. Maximum working temperature: 170℃.