Welded fin tube is a kind of high-efficiency heat exchange element. It significantly increases the heat exchange area by welding additional fins on the surface of the base tube, thereby improving the heat transfer efficiency. It is widely used in the field of industrial heat exchange.

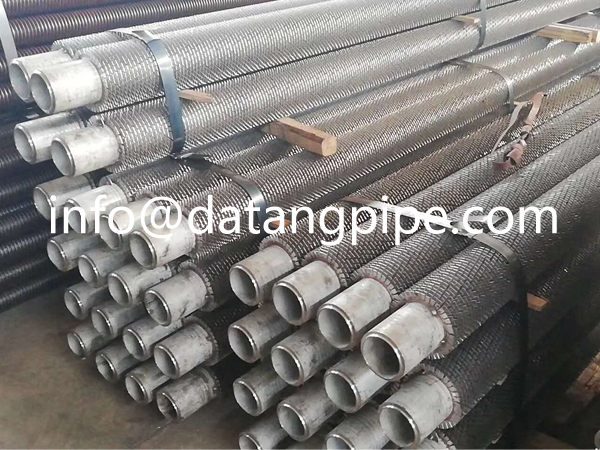

The welded fin tubes produced by Datang include high frequency welded fin tubes, laser welded fin tubes, H-type fin tubes, serrated fin tubes, Longitudinal finned tubes, Studded fin tubes, etc. Welcome to consult.

What is a welded fin tube?

Welded fin tube consists of a base tube and fins welded on its surface. The two are firmly connected by welding process to expand the heat exchange surface area and enhance the heat exchange performance, which is different from other fin attachment methods (such as winding or extrusion).

Main welding process types of welded fin tubes :

High-frequency welding :

High-frequency current heating is used to achieve rapid fusion of fins and base tubes, which is suitable for mass production.

Laser welding :

High-energy laser beam is used to melt the contact parts to form a metallurgical bond. The weld quality is high and the heat-affected zone is small, which can realize precise and automated production.

General welding type :

Other welding methods (such as arc welding) are included to ensure the firm connection between the fins and the base tube, which is suitable for industrial-grade durability requirements.

Welded fin tube structure composition:

Base tube:

Usually made of metal materials such as carbon steel, stainless steel, copper or aluminum, with good thermal conductivity and mechanical strength, used to transport heat medium.

Fin:

Attached to the surface of the base tube through precision machining to increase the surface area, the material matches the base tube to ensure the heat conduction efficiency.

Working principle of welded fin tube:

The heat is transferred from the medium inside the base tube to the surface of the fin. The heat exchange process is accelerated by the increased surface area of the fin, achieving efficient heat dissipation or heat absorption, suitable for high temperature and high pressure environment.

Performance advantages of welded fin tube:

The heat exchange efficiency is significantly improved and energy consumption is reduced;

The weld has high strength, strong corrosion resistance and long service life;

The manufacturing process is environmentally friendly, the heat-affected zone is small, and the performance of the parent material is maintained;

A wide range of applicable materials can be customized to adapt to different working conditions.

Application areas: Refrigeration and air conditioning (evaporator, condenser), industrial boilers, petrochemical equipment, energy and power systems (fluid heating/cooling), as well as HVAC and greenhouses, to ensure the stability and energy saving of thermal management.

In summary, the core of welded finned tubes lies in the application of welding technology, which realizes efficient and reliable heat exchange and is a key component of modern thermal equipment.